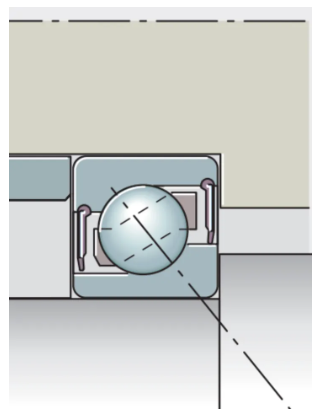

Angular contact ball bearing is a commonly used bearing type, which requires good rotational speed performance and load bearing performance. Compared with deep groove ball bearings, in addition to good radial load carrying capacity, there is a very good axial load carrying capacity. At the same time, due to angular contact ball bearing unique structure and load-bearing characteristics, its can only carry axial load in one way (single bearing), it also puts forward some requirements for the use of the bearing. First, we observe the internal structure of angular contact ball bearings, as shown below:

As can be seen from the figure, the internal structure of the angular contact ball bearing determines that the bearing can only withstand the axial load in one direction, and the direction of the load is the direction between the thick edge of the bearing inner ring and the thick edge of the bearing outer ring. If the bearing bears the opposite axial load, then the bearing will appear to be detached or detached, and the bearing rolling element can not form a pure rolling phenomenon, which leads to the bearing heat, wear phenomenon, the bearing will fail early.

Therefore, when the angular contact ball bearing is put into use, it is necessary to avoid the axial load opposite to its axial carrying capacity. How do you do that? This is what we call axial preload.

It has been described earlier that when a single angular contact is running, it is necessary to avoid the axial load inside the bearing that is opposite to its axial load carrying capacity, so it is necessary to apply a preload in the direction of its axial load carrying capacity. In the figure above should be the direction of the bearing from the thick edge of the outer ring to the thick edge of the inner ring.

Then the load should be how much? From the reasons for the axial preload of single row angular contact ball bearings introduced above, it can be seen that this preload is to avoid the reverse axial load in the outside world. That is to say, if there is a reverse axial load outside the bearing, the preload of the bearing should be able to offset this load. From this, it can be concluded that the axial preload should be greater than the possible external reverse axial load.

In addition, you should also consider the reverse axial load, the inside of the bearing load should meet the requirements of the minimum load. That is, a minimum bearing load is added to the maximum reverse axial load.

Site factors, if any, of course, also need to join.

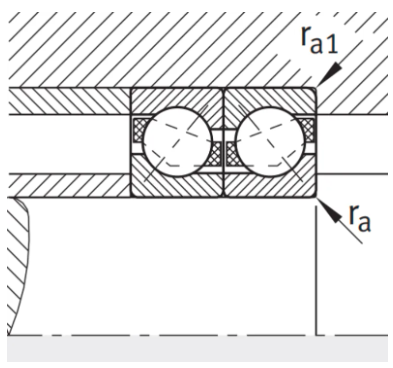

Since a single angular contact ball bearing can only withstand one-way axial load, it is used to install diagonal contact ball bearings face to face or back to back in bidirectional load conditions. Both mounting methods use two single-row angular contact ball bearings that are mounted together in opposite axial bearing directions. If the thick edge of the outer ring is installed together, it is back-to-back installation, if the thin edge of the outer ring is installed together, it is face to face installation. Whether installed face to face or back to back, the two angular contact ball bearings each bear the axial load in one direction. As shown in the picture below:

The picture shows a diagonal contact bearing mounted back to back. One on the left side of the shaft bearing under axial load from left to right, the right of the shaft bearing under axial load from right to left. From this diagram, for the paired angular contact ball bearings, the axial load in either direction will be borne by one of the bearings. Therefore, pretightening is generally not carried out by external application of axial preload. However, this does not mean that angular contact ball bearings mounted face to face or back to back cannot be preloaded. So with this configuration of bearings, how is the axial preload applied to the two bearings?

Look at the picture below:

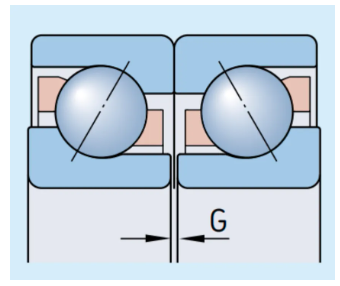

This diagram is of a back-to-back mounted diagonal contact ball bearing. It is not difficult to find in the figure that when the angular contact ball bearing has 0 internal clearance, its end face is not necessarily on a plane. The example in the figure is an angular contact ball bearing with a thicker edge than a thinner edge. When the thick edge of such two bearings is pressed, there is a gap between the thin edge, if the thin edge is also pressed by an external force, then there is a negative clearance inside the bearing, that is, there is a pre-tightening.

If the size of the thin and thick edges is controlled in the bearing production, the preload force inside the two paired bearings can also be controlled. In fact, in the production and use of bearings, this is indeed the operation. This is why when two single-row angular contact ball bearings are paired, they need to be paired. This assembly work is essentially to control the end size to control the internal preload force (clearance) of the bearing after installation.

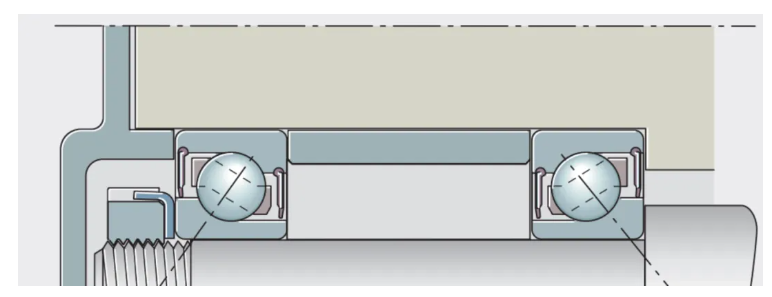

In addition to angular contact ball bearings with two bearings mounted together facing each other or paired back to back, sometimes two angular contact ball bearings are used for cross-positioning structures on both sides of the shaft. As shown in the picture below:

In the figure, the two angular contact ball bearings have no shaft ends, and the bearings are separated by spacers. At this time, the internal clearance of angular contact ball bearings is controlled by the size of the spacer ring. For the back-to-back angular contact ball bearings in the figure, if the length of the spacer ring is large, the internal preload of the bearing is large, and the reverse is small.

In the preload control of the diagonal contact ball bearing mentioned above, the user can also affect the internal clearance of the bearing by controlling the match between the bearing inner ring and the shaft. This calculation of the amount of clearance reduction will be written separately.

In short, after the installation of the diagonal contact ball bearing, the internal clearance under stable working conditions is the common result of the external control end size, the matching size between the bearing inner ring and the shaft, and the amount of clearance reduction affected by temperature. The size of the final preload should ensure that when the bearing is subjected to any axial load, the angular contact ball bearing at the non-loaded end should not be removed on New Year's Eve (the load is greater than the minimum load).

For industrial motor applications, pairing angular contact ball bearings are generally installed together directly, eliminating the need for pairing calculations and adjustments. However, for some gearbox applications, this calculation is necessary.