In the field of steel trade, the following terms are common terms, understanding their definitions and differences will help us to better carry out trade and production activities.

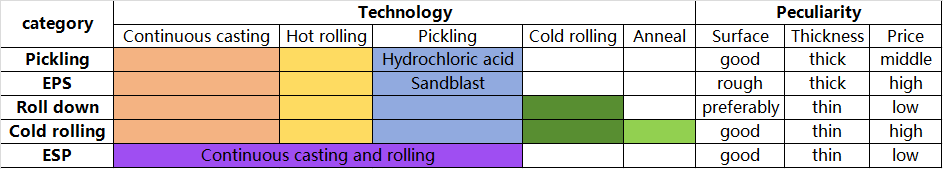

Pickling: that is, "hot-rolled pickling sheet coil", mainly refers to the hot-rolled steel coil treated by the traditional hydrochloric acid pickling process. The process involves dipping a hot-rolled steel coil into a solution of hydrochloric acid and removing the surface iron oxide through a chemical reaction to obtain a clean surface. After pickling, the product is usually smoothed to adjust to the appropriate surface roughness.

It is important to note that pickling products cannot be directly identified by brand name alone, as they share the same brand name as hot-rolled products. To distinguish pickling products, rely on the category description in the warranty, such as: Pickling SPHC, pickling DD11, etc.

Hard rolling: Usually refers to the product of hot rolled steel coil after pickling, rolling through the cold rolling mill to thin, but not annealed.

On e-commerce platforms, you may see a logo such as CDCM-SPCC, which represents the rolled hard coils produced by acid tandem mills.

Cold rolling: Rolling hard rolled products that have been fully or incompletely annealed. In the trade, the common cold rolled grades are SPCC, DC01 and so on. Even partially incompletely annealed products, such as DC01 C590 or SPCC 4B, fall into the cold-rolled category.

ESP: that is, "cold forming", refers to the hot-rolled acid-washed thin strip steel produced by the ESP (continuous casting and rolling) process. Cold-formed coils on the market are usually pickled and leveled to replace some cold-rolled structural steel. The commercial mass production of cold forming was first realized by Rizhao Iron and Steel, whose grade RECC is widely known, and the continuous casting and rolling process grades of other manufacturers, such as MCFC, are also more common now.

EPS: that is, "acid-free pickling", also known as environmental pickling or mechanical pickling. This process does not use a hydrochloric acid solution, but uses mechanical methods (such as sandblasting) to remove the surface of the hot rolled steel coil. Because the sand used should not be too fine, EPS pickling board surface roughness is high, so it is not suitable for parts with high surface quality requirements.

Here are answers to some frequently asked questions in steel trading:

Is pickling cold rolling or hot rolling?

Pickling is the process of removing the surface oxidation scale of the hot rolled steel coil by the pickling unit, so it belongs to the follow-up treatment stage of the hot rolled product, rather than cold rolling.

Is cold forming cold rolling or hot rolling?

Cold forming refers to the hot-rolled acid-washed thin strip produced by the ESP continuous casting and rolling process, so it is a kind of hot-rolled product, although the name has the word "cold", but not through the cold rolling process.

Is hard rolling the same as cold rolling?

Hard rolling is different from cold rolling. Hard rolling refers to the hot rolled steel coil after pickling, cold rolling mill rolled thin but not annealed product. Cold rolling, on the other hand, is a hard roll that has been completely or incompletely annealed. Therefore, rolling is the previous stage of cold rolling.