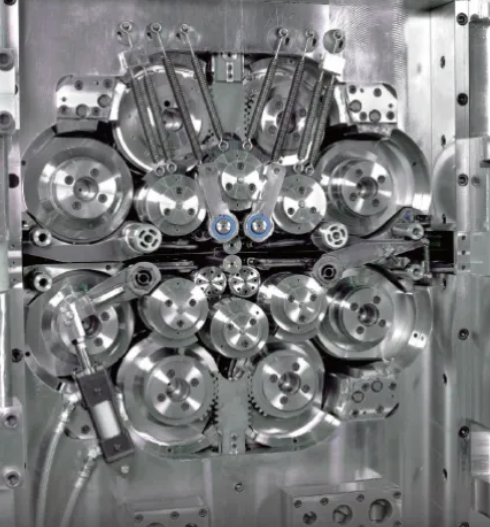

The 20-high rolling mill is widely used for rolling cold-rolled stainless steel, silicon steel, high-strength metal and alloy thin strips and extremely thin strips. It accounts for almost 96% of the world's stainless steel production.

Generally, the backing bearings of a 20-high rolling mill are reasonably configured as one for two, which is convenient for ensuring the effective operation of the rolling mill when bearing damage or returning to the factory for grinding is found during maintenance.

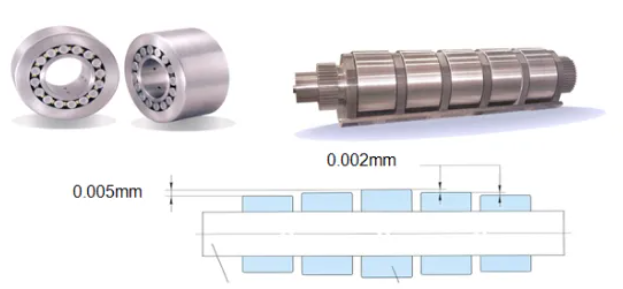

The precision requirements for the backing bearings of the twenty rolls are high. The H value of the backing bearings in the same group should be within 0.006, and the H value between adjacent ones should be within 0.002. The rotational accuracy of the bearings should reach P4 grade. For this reason, the periodic maintenance of backing bearings is of great significance. It requires not only the guarantee of process order such as maintenance norms, but also the allocation of dedicated personnel with rich experience, as well as the provision of specialized backing bearing testing equipment and sufficient spare parts.

It is very important to establish a maintenance ledger for the backing bearings: The maintenance of the backing bearings of the support rollers should be handled by a designated person. A ledger should be established to record information such as the saddle number, position, the time of the bearings getting on and off the machine, and the inspection status of the bearings.

During each cycle of use and maintenance of the backing bearing, a thorough cleaning of the bearing must be carried out first. The outer ring, rolling elements, cage, inner ring and other components of the bearing should be visually inspected, and an assessment should be made based on the extent of damage. Intact bearings can continue to be used, while damaged bearings should either be maintained on-site, returned to the factory for repair, or scrapped, etc.

When the bearings are severely worn or have parts replaced, they should be re-inspected and reassembled for use.

During disassembly, inspection, maintenance and other processes, proper markings should be made to prevent misalignment.

The appearance inspection of the outer diameter of the bearing should be carried out to check for dents, deep indentations, scratches, spalling and other conditions. If necessary, the outer diameter should be polished or ground. After grinding, it needs to be inspected and reassembled before it can be used again. The amount of bearing grinding should be determined based on specific circumstances. After grinding, it is necessary to ensure that the H value and diameter jump of the same group meet the technical requirements.

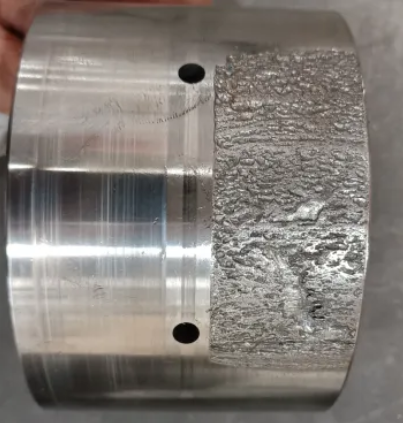

The appearance inspection of the outer ring end face: When the rolling parameters of the rolling mill are improperly selected or adjusted, the outer ring end face of the backing bearing will be subjected to a large axial force on one side. The bakedwood gasket will rub against the bearing end face, causing scratches on the bearing end face. In severe cases, scratches and hairline marks may occur on the bearing end face, and the outer ring of the bearing may crack and be damaged due to the hairline marks.

Check the raceway of the outer ring of the bearing for any scratches, pits or spalling. Handle or replace it according to the extent of the damage.

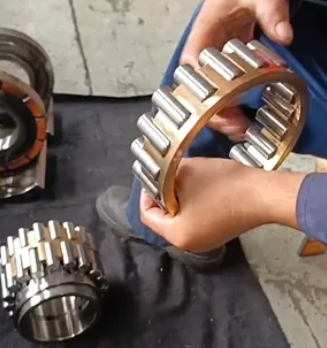

The cage is a very important component in a bearing. Generally, the material of the cage for backing bearings is mostly brass cages, which are relatively softer than the steel rolling elements and rings of the bearing. When subjected to large axial forces or when the rolling elements slip or twist, it is prone to collision and friction with the rolling elements, resulting in copper shavings falling off or burrs at the corners. Therefore, the cage also needs to be carefully inspected.

The rotational accuracy of the backing bearing reaches P4 grade, and the dimensional accuracy requirements for the rolling elements are extremely high. Check the appearance of each rolling element to see if there are any scratches, chamfers, burrs, pockmarks, spalling, etc. Analyze the lubrication and force conditions of the bearing based on the damage phenomena. If the damage is severe, replace the rollers in time. During the inspection of the rolling elements, prevent cross-contamination.

Check the inner ring of the bearing for any pockmarks or peeling, and make proper markings. The inner ring of the backing bearing serves as a supporting component and does not rotate during operation. The damage to the inner ring is mainly concentrated in the load zone. The end face of the inner ring is marked with an arrow for detecting the H value and a load zone mark. By using and replacing the load zone, the impact of inner ring raceway damage on bearing accuracy can be eliminated. By replacing the load zone, the influence of inner ring spalling on the rolling elements and appearance can be eliminated, which can extend the service life of the bearing.

The backing bearing must be left for one cycle after being taken off the machine for maintenance before being put back on the machine for continued use. This is mainly to release the organizational stress generated inside the bearing during the rolling process. During maintenance, it is best to immerse the bearings in hot oil at 80 to 100°C and keep them warm for 24 hours to release internal stress through aging or high temperature.

After the bearing inspection, assemble each component in sequence. Rotate the bearing to check if it rotates normally without damping or jamming. If not, disassemble it for inspection to eliminate the cause.

When installing the backing bearing onto the saddle, burrs and foreign objects on the shaft, saddle, roller box, gasket and other related parts should be removed. Check the oil passage and oil holes to ensure they are unobstructed. If it is difficult to install and knocking is necessary, use a copper hammer to gently ta

For ABCD rollers, new or intact bearings should be used as much as possible. Defective bearings should be used for EFGH rollers as much as possible.