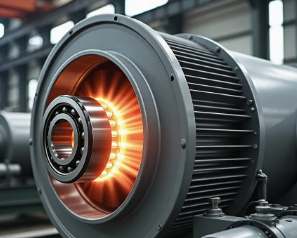

The points where the bearing gets hot can help determine the cause of the fault:

1. Uniform heating

If the entire bearing heats up uniformly, it might be due to either too much or too little lubricating grease, or insufficient cooling of the bearing.

2. Local fever

If a certain part of the bearing gets hot, it may be due to bearing damage, improper assembly of the bearing or the clearance adjustment of each part of the bearing housing not meeting the requirements.

3. Heating of the outer ring of the bearing

If the outer ring of the bearing gets hot, it might be due to an overly loose or tight fit between the bearing and the shaft, or between the bearing and the end cover, or insufficient cooling of the bearing housing.

4. Heating of the inner ring of the bearing

If the inner ring of the bearing gets hot, it may be due to bearing damage or the fit between the bearing and the shaft being too loose or too tight.

5. Heating of bearing rolling elements

If the rolling elements of the bearing get hot, it may be due to bearing damage or improper bearing assembly.

6. Heating of bearing cage

If the bearing cage gets hot, it may be due to bearing damage or improper bearing assembly.

7. Lubricating grease issues:

If too much or too little grease is added to the bearing, it will cause the bearing temperature to rise. When there is too much, the temperature will continue to rise to a certain point and then remain unchanged, and gradually decrease. When it is too little, heat is generated due to friction, causing the temperature of the bearing to rise.

Improper selection or contamination of lubricating grease makes it difficult to form a uniform lubricating oil film, leading to increased internal friction and wear of the bearing, and thus causing the bearing temperature to rise.

8. Cooling issues:

If the cooling is insufficient, such as when the pipeline is clogged or the cooler is improperly selected, it will cause the bearing temperature to rise.

9. Abnormal bearings

Bearing damage, poor assembly process or improper clearance adjustment of various parts of the bearing housing may all cause the bearing to overheat.

10. Vibration problem:

Poor alignment of the coupling, dynamic/static imbalance of the rotor, poor rigidity of the foundation, loose anchor bolts or rotational stall and surge may all cause the bearing to overheat.

11. Other issues:

Poor sealing between the inner and outer covers of the bearing and the entry of foreign objects into the bearing may also cause the bearing to overheat.

Provide a detailed introduction to the types of temperature differences caused by bearing heating and the corresponding faults

1. The temperature difference between the inner and outer rings of the bearing is too large

Phenomenon: The temperature of the inner ring is significantly higher than that of the outer ring (for example, the temperature difference exceeds 10℃).

- Possible causes:

- Too tight installation: The interference fit between the inner ring of the bearing and the shaft is too large, resulting in intensified internal friction.

- Insufficient lubrication: Uneven distribution or insufficient amount of grease, resulting in lubrication failure of the inner raceway.

Axial load offset: The load is concentrated on one side of the roller, causing local overheating.

- Inspection and Resolution:

Check the installation fit dimensions and recalculate the interference fit if necessary.

Replenish or replace the grease and ensure it is evenly applied.

Adjust the axial preload or check whether the load distribution is uniform.

2. Abnormal temperature differences between the bearing and adjacent components

Phenomenon: The temperature of a certain bearing in the same equipment is significantly higher than that of other bearings of the same type.

- Possible causes:

Uneven load: Design flaws in the mechanical structure cause a single bearing to bear additional loads.

- Assembly error: The bearing is installed at an Angle or the axis is not aligned, causing abnormal friction.

- Local wear: There are tiny cracks or spalling in the raceways or rolling elements.

- Inspection and Resolution:

Use a vibration analyzer to detect the operating vibration frequency and locate abnormal points.

Check the alignment of the shaft system and adjust the couplings or bearing housings if necessary.

Non-destructive testing (such as ultrasonic flaw detection) is used to check for internal damage.

3. The temperature of the bearing keeps rising and fluctuates irregularly

Phenomenon: The temperature gradually rises without any periodic change.

- Possible causes:

- Lubrication failure: Oxidation and deterioration of grease or contamination (such as moisture, metal debris).

- Long-term overload: The design load does not match the actual working conditions.

- Seal failure: External contaminants invade the interior of the bearing.

- Inspection and Resolution:

Take samples to analyze the composition of the grease and replace it with qualified grease.

Check the equipment load parameters, optimize the mechanical transmission ratio or replace the bearings with larger specifications.

Check the integrity of the seals and replace the dust-proof/water-proof sealing structure.

Temperature monitoring and fault diagnosis methods

1. Temperature measurement tools and methods

Infrared thermometer: Quickly detects the surface temperature of bearings and is suitable for non-contact measurement.

- Temperature sensor: Embedded installation, real-time monitoring of the temperature of the rolling elements or cage.

- Thermal imager: Visualize heat distribution, locate high-temperature areas and conduction paths.

2. Temperature data analysis logic

- Baseline comparison: Compare with historical data or similar equipment to identify abnormal temperature rise trends.

- Temperature difference threshold: Set the safety threshold for the temperature difference between the inner and outer rings and the same group of bearings (such as ≤5℃).

- Correlation parameter analysis: A comprehensive judgment is made by combining vibration frequency, noise decibels, current fluctuations, etc.

Typical fault cases and solutions

Case 1: The outer ring of the fan bearing is abnormally hot

Phenomenon: The temperature of the outer ring is 15℃ higher than that of the inner ring, accompanied by periodic noise.

Diagnosis: The bearing housing has poor heat dissipation, and external heat cannot be effectively conducted.

Solution: Add heat sinks or switch to forced air cooling, and optimize the ventilation path.

Case 2: The bearing at the input end of the gearbox keeps heating up

Phenomenon: The temperature rises from 60℃ to 90℃, and the grease turns black.

Diagnosis: Metal debris mixed into the grease causes abrasive wear.

Solution: Thoroughly clean the bearings and replace them with high-viscosity grease, and enhance the filtration system.

Preventive maintenance suggestions

Regular lubrication and maintenance:

- Develop a lubrication cycle table based on the working conditions to avoid overlubrication or underlubrication.

By adopting the "waste oil analysis" technology, it can issue early warnings for excessive metal particle content.

2. Installation specification control

- Use a heating jacket or hydraulic installation tool to avoid deformation of the inner ring due to knocking.

Check the machining accuracy of the shaft and the bearing housing to ensure the smoothness of the mating surfaces.

3. Environmental Adaptability Design

In high-temperature or humid environments, high-temperature resistant grease (such as molybdenum disulfide based) should be selected.

Install protective covers to reduce the invasion of dust and moisture.