Four-row cylindrical roller bearings are often selected as support roller bearings of metal calendering mill in recent years because of their advantages such as separability after installation, easy control of manufacturing precision, high limit speed, strong bearing capacity, interchangeable parts, easy inspection, and quick disassembly and assembly of fast rollers. However, in the process of application in this field, the inner ring sometimes cracks linearly. It often leads to belt breaking and stop failure of rolling mill due to on-line holding and burning of bearing, which seriously affects the normal operation of rolling mill.

The on-site faults are as follows:

Axial cracking occurs in the inner ring of four row cylindrical bearings on one side of the spacing ring;

Double row tapered bearings are locked, mainly for a row of rolling body close to the main bearing, inner ring end face and distance ring high temperature adhesion;

Position: lower roll operating side;

Based on the fault performance and field observation, the following analysis and summary are made:

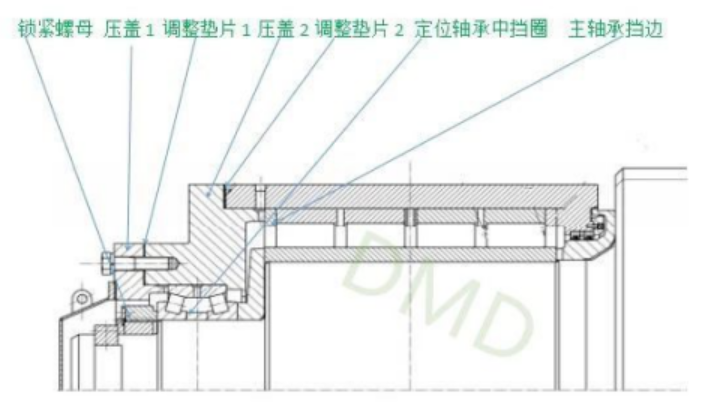

1. Roller assembly structure

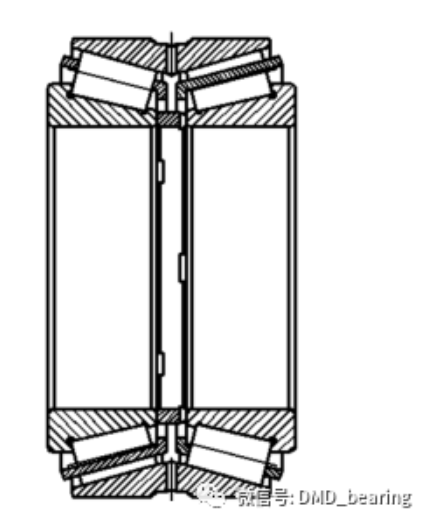

Typical bearing configuration, double row cone plus four row cylinder, double row cone used to withstand the axial load generated by rolling, limiting the two-way displacement of the shaft. The four columns bear all the radial loads produced by rolling.

Two, damage phenomenon

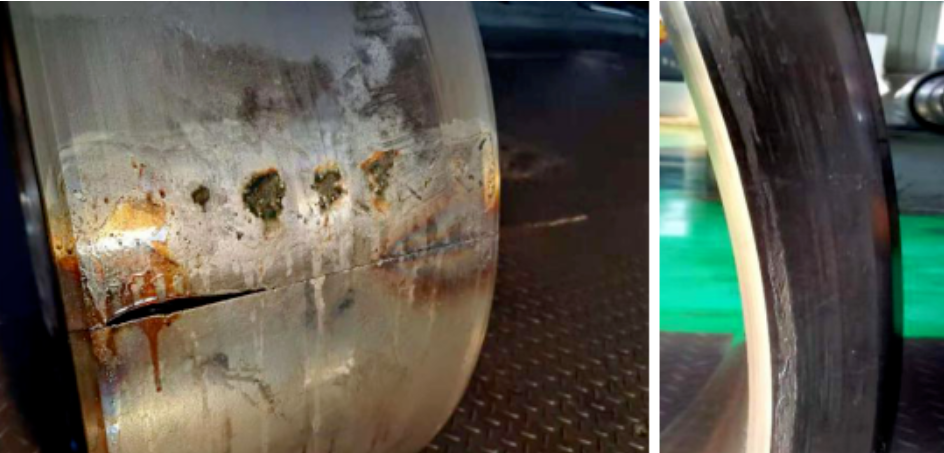

1. A row of positioning bearing rolling body is locked, the inner ring end face is attached to the distance ring at high temperature, and the cage will disappear under high temperature rolling by 30%;

2. The inner ring of the bearing cracks by positioning the half sleeve of the bearing side, and the friction trace is obvious by positioning the bearing end face;

3. The inner diameter of the spacing ring and the end face of the fitting bearing have serious wear;

Iii. Reason analysis

1, first of all, the serious damage of the positioning bearing (double row tapered roller bearing) damage cause analysis, after the query positioning bearing online use for 460 days, has far exceeded the warranty cycle, at the same time through the burn debris, rolling body and inner and outer ring raceway careful inspection, raceway surface is no material surface fatigue spalling traces, It shows that each raceway surface is normal before burning. At the same time, combined with the above phenomenon 1, it is comprehensively judged that the burning of the bearing is caused by short time sticking resistance, so it further checks another set of undamaged bearings with the same use time to help find out the sticking resistance factors.

The appearance, raceway surface and surface of the rolling body were checked, and then the inner ring components in the two rows were rotated. It was found that the inner ring components in the first row of the main bearing were rotating abnormally, the cage was relatively loose, and the rolling body touched the bearing when the bearing was rotating upright, that is, the cage function failed. The function of the cage itself was to make the rolling body evenly divided on the circumference of the raceway in the inner ring. Maintain a certain distance to ensure that no contact occurs during high-speed rotation of the bearing. Once contact occurs during high-speed rotation, it is bound to cause the deformation of the cage, resulting in bearing sticking and bearing burning.

Analysis and judgment: Because the cage uses the hole for a long time, and the main bearing column bears a large axial load, so the main bearing column has a large relative wear, and the bearing works as an upright state, the cage will fall, the wear of the hole will lead to a larger fall, and then lead to the rolling body's contact, and the bearing sticking resistance will lead to the bearing burning.

To be continued.....