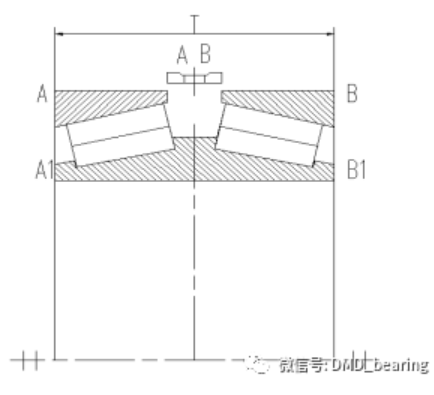

2. The second is the damage analysis of the inner ring cracking of the four-row cylindrical bearing. The external factors causing the cracking of the inner ring are mainly as follows, based on the bearing's mechanical characteristics and the installation and use of the inner ring.

The interference is too large

When the interference between the inner ring and the shaft is too large, the bearing is hot loaded to the back of the roll neck. Before the use of the machine, the inner ring will expand and crack during the cooling process or crack during the outside diameter grinding before the use of the machine.

The interference is small

When the interference between the inner ring and the shaft is small, the relative sliding friction between the inner ring and the shaft occurs during the operation of the bearing, leading to the cracking of the inner ring.

Face fitting friction

When the bearing is used on the machine, the inner ring and the distance ring have relative sliding friction, which leads to the fracture of the inner ring and the cracking of the inner ring. During the running of the bearing machine, the inner ring, the dynamic maze and the distance ring have relative sliding friction at the same time, which leads to the fracture of the inner ring and the cracking of the inner ring.

Analysis and judgment: comprehensive external cracking factors and phenomenon 2, 3 analysis, the roller diameter is measured, directly eliminate the problem of matching size, so there is sliding friction between the bearing inner ring end fittings and the inner ring, resulting in the inner ring end cracks, *** eventually lead to the axial cracking of the inner ring;

3, in order to corroborate the analysis results after the complete pickling inspection of the damaged inner ring, especially the end face state of the inner ring.

The results are as follows:

1. There are dense friction cracks on the end face of the inner ring in contact with the distance ring;

2. No friction crack on the other end face of the inner ring;

Through the distribution of cracks on the inner ring end face, it is found that there are dense cracks on the inner ring end face in contact with the spacing ring, but there is no cracks on the other side of the same inner ring. Therefore, it can be determined that the cracking of the inner ring is caused by the end face crack, and the end face crack is caused by the friction between the end face crack and the spacing ring, and the friction of the spacing ring is caused by the burning and locking of the positioning bearing.

Iv. Preventive measures

The main line of the burning failure is: positioning bearing burning and locking → adhesive chain spacing ring → relative sliding friction between spacing ring and inner ring end face → inner ring cracking

From the above analysis, the positioning bearing burn is the guiding point of the fault, and the inner ring end face friction and axial force is the ultimate cause of inner ring cracking, so the prevention of positioning bearing lock burn and prevent the relative sliding friction between the distance ring and the inner ring end face can prevent the occurrence of the fault.

Positioning bearing

The following checks should be carried out on the positioning bearings with a long overdue use time:

1. Whether the cage becomes larger due to the wear of the pocket hole for a long time, leading to the larger clearance between the cage and the rolling body, and whether the spacing between the rolling bodies becomes significantly smaller or directly touches the bearing;

2, the inner ring wear is obvious, there is no size change, resulting in bearing clearance change;

3. If there is obvious fatigue and serious color change on the surface of the rolling body, the bearing needs to periodically reverse side A and side B of the whole, so as to prevent the single row rolling body from always being used in the same position;

Spacing ring

1. Check the inner diameter of the spacing ring for obvious wear, check the size of the inner diameter, and ensure that the fitting with the journal is a transition fit or interference fit.

2, change the connection with the shaft, the inner diameter keyway is connected with the shaft or the end face of the hole using bolts and roller connection.