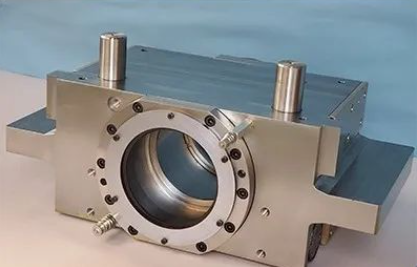

A bearing seat is a device used to support and hold bearings, usually made of cast iron, cast steel and other materials. It provides a stable installation position for the bearing, so that the bearing can operate normally, thus ensuring the smooth operation of the entire mechanical system.

Bearing seat The role of the bearing seat mainly has the following aspects:

Support and fixed bearings: provide a stable installation position for bearings, ensure the correct positioning of bearings in mechanical equipment, reduce the shaking and loosening of bearings during operation, so that the shaft can rotate or move smoothly.

Bearing load: It can bear various loads in mechanical operation, such as radial force, axial force, bending moment, etc., and transfer it to other parts of the supporting bearing, while ensuring the uniform distribution of load to reduce the force on the shaft and bearing, thereby improving the life and reliability of the bearing.

Positioning and guidance: through the design of a reasonable structure and accurate size, ensure that the actual position and Angle of the bearing are consistent with the design value, ensure the stability and accuracy of the machine during operation, and guide the shaft to rotate or move in the specified direction.

Vibration and noise reduction: absorb and disperse the vibration and impact force generated during mechanical operation, reduce the impact on bearings and other parts, reduce the noise of the machine, protect it from damage, and improve the stability and reliability of mechanical equipment.

Adjust and control the position of the shaft: when the bearing due to wear, deformation and other reasons cause the working performance of the machine to decline, the position and Angle of the bearing seat can be adjusted to restore the machine to the normal working state and extend the service life of the machine.

Sealing and protection: part of the bearing seat has a sealing structure, which can prevent dust, water, impurities, etc. from entering the bearing inside, and keep the lubricating oil inside the bearing clean and lubricate without leakage, so as to ensure the normal operation and service life of the bearing.

In summary, the bearing seat plays a crucial role in the mechanical system. It not only ensures the stable operation of bearings and the normal function of mechanical equipment, but also improves the performance and reliability of the entire system in a variety of ways.

In the process of use, the bearing seat will be worn in the case of repeated disassembly, bearing breakage, plastic deformation under the force (such as ellipse, taper, etc.).

Causes ellipse, subsidence and other problems scrapped bearing seat

The impact of bearing seat wear on bearings is mainly reflected in the following aspects:

1. Affect the normal operation and life of bearings

Reduced matching accuracy: After the bearing seat is worn, the gap between the bearing and the bearing seat will increase, resulting in unnecessary movement and vibration of the bearing during operation. This not only affects the normal operation of the bearing, but also reduces its service life.

Increase bearing wear: Due to the decline in matching accuracy, the bearing will be subjected to greater friction and impact during operation, thus accelerating the wear of the bearing, and may even lead to bearing damage, such as cracks, fractures and other phenomena.

2. The device running efficiency is reduced

Increase energy consumption: bearing seat wear will cause the bearing to produce more friction resistance during operation, and more energy needs to be consumed to overcome these resistance, resulting in an increase in the energy consumption of the equipment and a reduction in energy efficiency.

Vibration and noise: the bearing seat after wear can not provide stable support for the bearing, so that the bearing produces abnormal vibration and noise during work, which will not only affect the working environment, but also may cause damage to other components.

3. The positioning accuracy and stability of the device are affected

Reduced positioning accuracy: In some equipment with high position accuracy requirements, such as CNC machine tools, precision instruments, etc., the wear of the bearing seat will lead to changes in the position of the bearing, which will then affect the positioning accuracy of the equipment, so that the processing or measurement results are biased.

Stability decline: After bearing housing wear, the operating stability of the equipment will be affected, prone to shaking, offset and other problems, which for some high-speed operation or high stability requirements of the equipment, may cause serious safety accidents.

4. Increase maintenance costs

Frequent maintenance and replacement: In order to ensure the normal operation of the equipment, it is necessary to repair or replace the worn bearing seat in time, which increases the maintenance workload and maintenance costs of the equipment, including parts procurement, labor costs, downtime losses, etc.

Affecting the production schedule: the equipment is shut down for maintenance due to the wear of the bearing seat, which will lead to the delay of the production schedule and bring economic losses to the enterprise.

Therefore, in order to ensure the normal progress of production, we should pay more attention to the wear of the bearing seat, so as to minimize consumption and improve production efficiency.

The picture shows the inside of the abandoned bearing seat