The types of cracks are numerous and diverse: raw material cracks, heat treatment cracks, forging cracks, etc., which make people dizzy. How to identify them is a very important course, so that it is easy to accurately find in which process the crack occurs, and is conducive to analyzing the cause of the crack.

First of all, it is necessary to determine the concept of "raw material cracks" and "forging cracks", and the cracks that appear after forging should be understood as "forging cracks", but the main factors that lead to forging cracks can be divided into:

1. Forging cracks caused by raw material defects;

2. Forging cracks caused by improper forging process.

From the macroscopic shape of the crack, the transverse crack is generally unrelated to the base material, and the longitudinal crack needs to be analyzed in combination with the crack shape and forging process.

There is decarbonization on both sides of the crack, which must be generated in the forging process, as for the raw material or the forging process, which needs to be analyzed according to the metallography and process.

For the same batch of the same type of workpiece, the forging cracks are basically in one position, and the extension is relatively shallow under the microscope, and there is decarbonization on both sides. The material cracks do not necessarily appear repeatedly in the same position, and the depth under the microscope is different. See more and analyze more, there are certain rules.

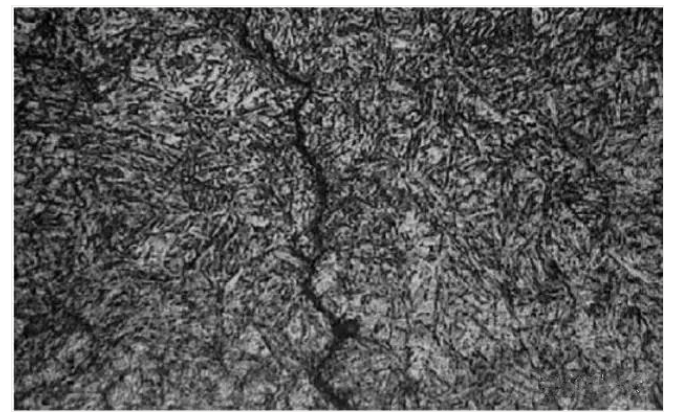

The material cracks are mostly consistent with the material longitudinal. There are two kinds of forging cracks, one is caused by overheating and overburning, and there is oxidation and decarburization near the crack. There is also a cold iron will also cause cracking, which is a phenomenon of lattice damage and tearing. It can be distinguished from the metallography.

Purpose of forging:

1, forming requirements;

2, improve the internal structure of the material, refine the grain, uniform element composition and organization;

3, make the material more dense (forged material inside the original unexposed air shrinkage or loose, etc.), streamline distribution is more reasonable;

4, through a reasonable post-forging heat treatment, for the next process service.

Therefore, forging and forging of certain internal defects in raw materials is the responsibility. Large castings and forgings are often started directly from the ingot forging, and there must be a large number of smelting defects inside the ingot, obviously, reasonable forging can be the so-called "defects" forging. Therefore, the rationality of the forging process is the main reason for determining whether the forging will crack.

Of course, relative to a stable forging process, if a clear raw material defect grade control requirements are put forward for raw materials before forging, when the raw material defect grade exceeds the requirements and the cracking phenomenon occurs under the original forging process, we can consider it as "forging cracks caused by raw material defects".

The concrete analysis of the specific problem of the crack problem, combined with the analysis of the process, including whether the heating process has a protective atmosphere should be considered, and the forging should be the crack forging of the raw material. The oxide skin is usually dense and gray, and the dirty things caused by the sample preparation process are very loose and black in color, and it is known at high times that it is impossible to distinguish the direct energy spectrum.

1 Forging crack

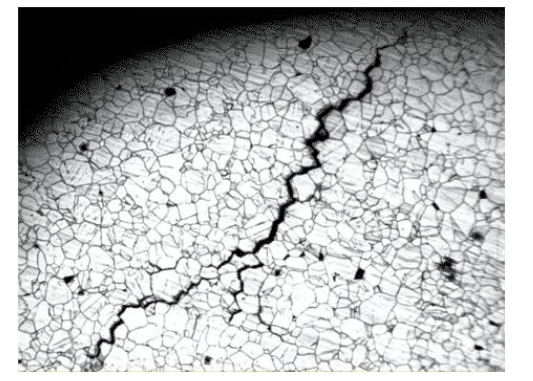

Forging cracks are generally formed at high temperature, and when forging deformation, due to the expansion of cracks and contact with air, it can be seen under a 100X or 500X microscope that the cracks are filled with oxide, and both sides are decarburized, and the organization is ferrite. Its morphological characteristics are that the cracks are relatively robust and generally exist in multiple forms, without detailed tips, relatively round and pure, and without detailed direction. In addition to the above typical forms, sometimes some forging cracks are relatively fine. The cracks are not fully decarburized but semi-decarburized.

Typical forging crack examples:

Edge more oxide.

2 Heat treatment crack

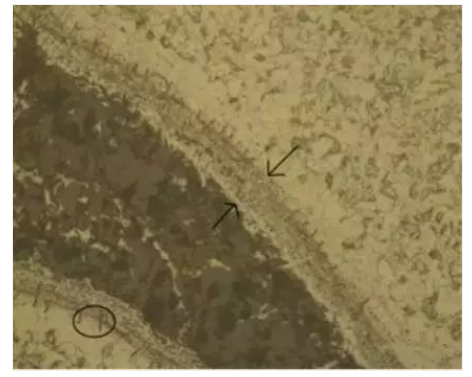

There are obvious differences in the properties and forms between the cracks in the process of quenching heating and those in the process of forging heating. For structural steel, the heat treatment temperature is generally much lower than the forging temperature, even high-speed steel, high alloy steel, the heating and holding time is far less than the forging temperature. Due to the high heating temperature of heat treatment, too long holding time or rapid heating, early cracking will occur in the heating process. Cracks distributed along coarser grain boundaries are generated. There is a slight decarburization on both sides of the crack, and the heating speed of the part is too fast, which will also produce early cracking. There is no obvious decarburization on both sides of the crack, but the crack and its tail are filled with oxide skin. Sometimes due to the failure of high temperature instruments, the temperature is very high, resulting in the organization of the parts is very coarse, and the cracks are distributed along the coarse grain boundary.

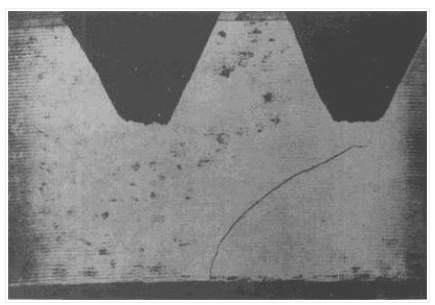

Typical hardening crack examples:

At 500X, it is serrated, the crack at the beginning end is wide, the crack at the end is fine to none, no abnormal metallurgical inclusion is found at the crack, no decarburization phenomenon, the crack is serrated extension, with the typical characteristics of quenched crack.

3 Causes of forging cracks and heat treatment cracks

1, forging cracks cause: steel in the forging process, due to the surface and internal defects of steel, such as hair lines, sand holes, cracks, inclusions, subcutaneous bubbles, shrinkage holes, white spots and interlayers, etc., may become the cause of forging cracking. In addition, due to poor forging process or improper operation, such as overheating, overburning or the final forging temperature is too low, and the cooling speed after forging is too fast, it will also cause forging cracking.

2, the cause of heat treatment cracks: quenching cracks are macro cracks, mainly caused by macro stress. In the actual production process, the steel workpiece is often due to unreasonable structural design, improper steel selection, incorrect quenching temperature control, quenching cooling rate is not appropriate and other factors, on the one hand, increasing the internal stress of quenching, will make the formed quenching micro crack expansion, the formation of macro quenching crack, on the other hand, due to the increase in the sensitivity of micro crack, increase the number of micro cracks, increase the number of micro cracks. The brittle fracture resistance Sk of steel is reduced, and the possibility of hardening crack formation is increased.

4 Factors affecting quenching cracking

There are many factors affecting quenching cracking, and here only a few cases that are often encountered in production are introduced.

1, the raw material has defects caused by quenching cracking: if the raw material surface and internal cracks or inclusions and other defects, not found before quenching, hardening cracks may be formed;

2. Cracking caused by inclusions: If the inclusions inside the parts are serious, or there are cracks hidden by the inclusions themselves, cracks will be likely to occur during quenching;

3. Quenching crack caused by poor original tissue;

4, quenching temperature caused by improper quenching crack: improper quenching temperature caused by parts quenching crack, there are generally two cases:

(1) The instrument indicates that the temperature is lower than the actual temperature of the furnace, so that the quenching temperature is high, resulting in quenching overheating, resulting in cracking of the workpiece. There are coarse grain and coarse martensite in all the microstructure of superheated quenching cracking.

(2) The actual carbon content of the steel is higher than the content specified in the steel grade, if the normal quenching process of the original grade is quenched, it is equal to increasing the quenching temperature of the steel, which is easy to cause overheating of the parts and grain growth, so that the quenching stress increases and causes quenching cracking.

5, quenching quenching caused by improper cooling: quenching due to improper cooling, will also cause parts quenching cracking accident.

6, quenching cracks caused by machining defects: due to poor machining, thick and deep knife marks are left on the surface of the parts, although it is a very simple part or not a place where the stress is concentrated, it will also cause cracking during quenching, or early damage during service.

7, the impact of the shape of the part on the quenching crack: the geometric shape of the part is unreasonable, or the thickness of the excessive section is large, and the crack is prone to stress concentration during quenching.

8. Cracking caused by not timely tempering: If not timely tempering after quenching, cracks may be caused by excessive quenching residual stress.

5 Crack resolution method

It is very important to distinguish whether it is a quenching crack, a tempering crack, a forging crack or a grinding crack, so that it is easy to accurately find which process the crack occurs and is conducive to analyzing the cause of the crack.

First, pay attention to the difference in the shape of quenching cracks and grinding cracks. For cracks that are not found during quenching but found after grinding, it is necessary to distinguish between quenching cracks and grinding cracks. When the crack is not attached to pollutants, it is easier to pay attention to the shape of the crack, especially the direction of the development of the crack. The grinding crack is perpendicular to the grinding direction, in the form of parallel lines, or in the form of tortoise-shell cracks. The depth of the grinding crack is shallow, and the quenching crack is generally relatively deep and large, which has nothing to do with the grinding side, and is mostly a linear knife-cut cracking.

Second, pay attention to where the crack occurs. Sharp concave and convex corners, holes at the edge, marking, stamping and machining caused by surface defects and other parts, in these parts of the cracks are mostly quenched cracks.

Third, by observing the crack section of the part to distinguish whether it is the crack caused by the quenching crack or the forging crack before quenching or other circumstances. If the crack section is white or dark white or light red (rust caused by water quenching), it can be determined as a quenching crack, if the crack section is dark brown, even the appearance of aerobic skin, it is not a quenching crack, the crack exists before quenching, is the crack formed when the part is forged or calendered, these cracks will be expanded by quenching. Because the quenching crack is basically formed below the MS point, its cross section will not be oxidized.

Fourth, in the microstructure, the quenching crack is broken along the grain boundary, if it is not broken along the grain boundary, but along the grain fracture, it is a fatigue crack.

Fifth, if there is a decarburization layer around the crack, it is not a quenching crack, but a crack that exists before quenching, because the quenching crack is generated during quenching cooling, and decarburization will never occur.