Cylindrical roller bearings come in single-row, double-row and four-row rolling element structures. Common cage structures in the market include comb-shaped, closed riveted, integral square hole, string column and pressed window steel cages.

Common materials for cylindrical roller bearing cages include pressed steel cages, nylon cages, machined steel cages, ductile iron cages, and brass cages, etc.

During the operation of the bearing, the cage has to withstand mechanical stress caused by friction, impact force, centrifugal force and inertial force. It may also be chemically affected by certain organic solvents or coolants, lubricants and lubricating additives. Therefore, the appropriate cage material should be selected according to the specific working conditions.

The maximum working temperature of a general stamped steel cage is 300°C.

The maximum operating temperature of the brass cage is 250°C.

The working temperature of the nylon cage is generally between +70 and -40 °C.

With the continuous application of cylindrical roller bearings in high-load and high-speed scenarios, the structural design concepts of cylindrical roller bearings have been innovated and explored, and the processing techniques have been constantly improved. The cage structure forms are diverse. Common cage structure forms for cylindrical roller bearings include:

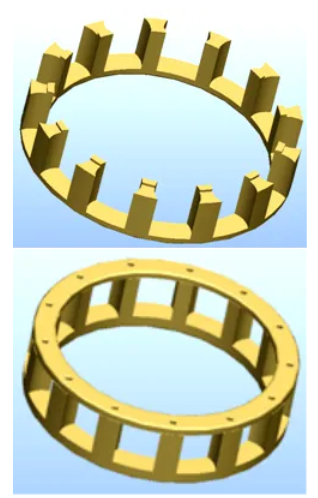

1.Comb type (four-row cylindrical roller bearing FC structure) : Easy to process, fully lubricated, and the outer ring of the bearing has a ball loading port structure design.

2. Closed type (two-body machining, self-riveting assembly EM structure) : Firm structure, high strength, enhanced load-bearing capacity, mostly used in motor bearings.

3. Closed type (two-body machining, riveted M structure) : The bearing assembly and riveting are simple, and it is used in ordinary working conditions with slightly lower load-bearing capacity.

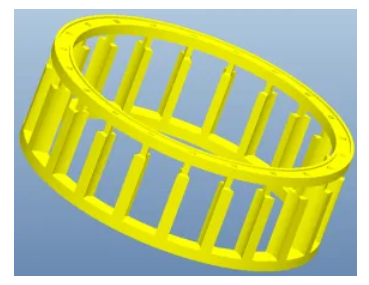

4. Closed type (integral, square hole structure) : The rollers are assembled by pressing in, the cage has good symmetry, and the center of mass coincides with the rotation center.

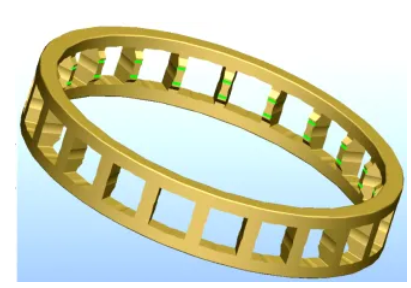

5. Closed type (spindle-shaped pocket structure) : Optimize the structural design, improve the cage and roller guide points and local optimization design, reduce mutual friction and collision, improve lubrication, and be suitable for high-speed working conditions.

6. Stamped steel cage: Reduces the weight and cost of the cage, increases the internal space and improves lubrication, suitable for specific high-temperature and other working conditions.

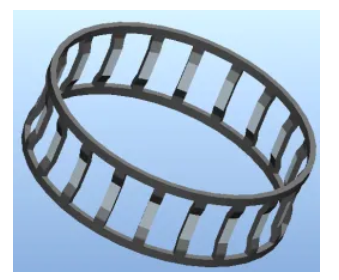

7. Column roller structure: By increasing the number of roller arrangements, it is more lubricated, facilitating periodic maintenance. The rollers operate synchronously with the cage, making it suitable for large-sized FCDP structure bearings.