A large number of application practices and life tests have shown that most bearing failures are due to fatigue of the contact surface. GB/T 24611-2020 /ISO15243:2017 lists fatigue as the first among the six common failure modes of bearings. Fracture, which is ranked sixth, is also caused by fatigue during its formation process and is called fatigue fracture. Typical fatigue failures are classified into sub-surface origin type and surface origin type.

I. Subsurface-originated fatigue

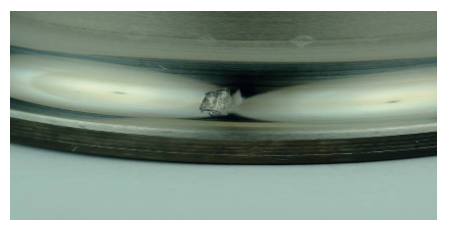

The maximum contact stress of rolling contact occurs at a certain depth beneath the surface. Under the repeated action of alternating stress, a fatigue source (microcrack) is formed at this location. The crack source gradually expands towards the surface under cyclic stress, forming open sheet-like cracks, which are then torn into sheet-like particles and peeled off from the surface, resulting in pockmarks and pits. If there are certain weak points or defects in the bearing steel at this location (common ones include non-metallic inclusions, air gaps, and grain interfaces of coarse carbides), it will accelerate the formation of fatigue sources and the propagation of fatigue cracks, significantly reducing the fatigue life.

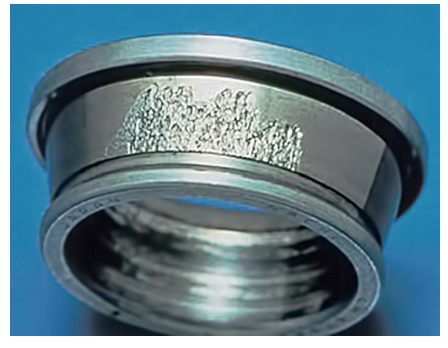

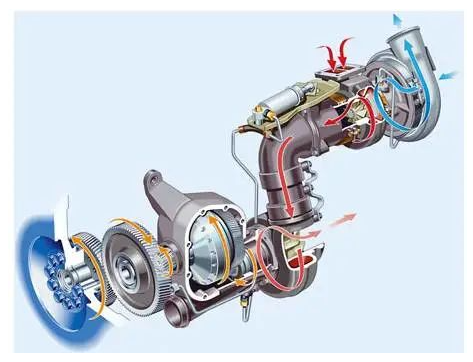

Subsurface origin type spalling on the rotating inner ring of deep groove ball bearings Ii. Surface-originated fatigue There are damages at the contact surface. These damages may be original, that is, scratches and dents formed during the manufacturing process, or they may be generated during use, such as hard particles in the lubricant or minor abrasions caused by the relative movement of bearing parts. There may be poor lubrication at the damaged area, such as a lack of lubricant or lubricant failure. Poor lubrication conditions intensify the relative sliding between the rolling elements and the raceways, resulting in microcracks at the root of the micro-protrusions at the surface damage sites. Crack propagation leads to the detachment of micro-protrusions or the formation of flaky spalling areas. This kind of peeling is relatively shallow and sometimes can be easily confused with dark gray etching spots. The expanded subsurface origin type spalling on the stationary inner ring of the tapered roller bearing Iii. Fatigue Fracture The origin of fatigue fracture is the fatigue yield formed by the assembly stress generated by excessive tight fit and the cyclic alternating stress. Once the balance among the assembly stress, alternating stress and yield limit is lost, fracture will occur along the axis direction of the ring, forming a penetrating crack. In practice, for bearings that fail during normal use, the damage is mostly as described above, that is, contact surface fatigue. Among the three types of fatigue failure, sub-surface origin fatigue is the most common. The bearing life calculation methods recommended by ASO281 and ISO281/amd.2 are based on sub-surface origin fatigue. Common anti-fatigue methods include: A. Heat treatment technology Heat treatment is a commonly used process method to improve the mechanical properties of materials. To meet the different usage requirements of parts made of different materials, different heat treatment processes need to be selected. The pre-heat treatment structure, quenching heating temperature, heating rate, cooling method (medium and rate), tempering temperature and time, etc. all have a significant impact on mechanical properties. It is necessary to optimize and combine numerous heat treatment parameters to achieve the best performance that suits the usage conditions, thereby extending the fatigue life of the parts. Build a virtual production platform for heat treatment and promote the transformation of heat treatment technology towards high-tech and knowledge-intensive. The optimization of heat treatment process parameters and the development of digital heat treatment technology are important prerequisites for achieving fatigue-resistant manufacturing.

B. Surface chemical heat treatment

The modification effect of surface chemical heat treatment mainly occurs on the surface. According to different application requirements, the chemical elements infiltrated can be selected. For instance, carburizing followed by quenching and tempering can enhance surface hardness, but the distortion of the workpiece is difficult to control. Nitriding, on the other hand, forms metal nitrides, which can achieve higher surface hardness, wear resistance, corrosion resistance and fatigue resistance, and the distortion of the workpiece is small, but the efficiency is not high. The co-infiltration process makes the hardness, wear resistance, corrosion resistance and fatigue resistance better, and the quenching distortion is less. However, the hardened layer is thin and it is not suitable for heavy-duty workpieces. The development direction of surface chemical heat treatment is to expand the application of low-temperature chemical treatment, improve the quality of the diffusion layer, accelerate the treatment process, and develop environmentally friendly processes, composite diffusion processes and analog digital treatment technologies.

C. Application of surface strengthening technology

Traditional surface strengthening techniques originated from the principle of cold working hardening, such as shot blasting, sandblasting, and shot peening. New surface strengthening techniques, such as laser surface hardening, laser shot peening surface hardening, ultrasonic rolling hardening, and chemical method surface hardening, have been successfully applied in many fields. New surface hardening technologies that combine various processes, such as the laser-shot peening process (laser shock treatment), High-energy pulsed laser is used to form shock waves on the surface of parts, causing compression and plastic deformation of the surface material and creating residual compressive stress on the surface, thereby enhancing the fatigue resistance (such as resistance to stress cracks and corrosion fatigue, etc.).

D. Surface modification technology

The commonly used surface modification techniques mainly include ion implantation and surface coating.

Ion implantation is a non-high-temperature process without the limitations of metallurgy and equilibrium phase diagrams. Different implanted elements and dosages can be selected according to different needs to achieve the expected surface properties. For example: Inject chromium ions to enhance the corrosion resistance and fatigue resistance of the base material; Boron ions are injected to enhance the anti-wear ability of the matrix.

Surface coating technologies include physical vapor deposition (PVD), chemical vapor deposition (CVD), radio frequency sputtering (RF), ion spraying (PSC), and electroless plating, etc.

In addition, the ion infiltration process uses high-voltage direct current to keep the elements to be infiltrated in an ionic state under a certain vacuum degree. The generated ion current bombards the surface of the workpiece, forming compounds on the surface to reduce friction and improve wear resistance.

E. Micro-machining and finishing technology

As an advanced manufacturing technology, high-precision micro-machining and blending, as well as finishing techniques, also play a significant role in enhancing the fatigue resistance of basic parts. Ultra-precision grinding and eddy current finishing are carried out with the aim of reducing the surface roughness of the workpiece. After processing, the physical and chemical properties, mechanical properties, and contour shapes at the contact points of the surface all undergo beneficial changes. This can correct the contact stress distribution, facilitate the formation of a dynamic lubricating oil film, and enhance the fatigue life.

F. Coordinate hardness matching

The hardness matching relationship of different parts can also coordinate the stress and strain transmission states at the rolling contact points, which has a significant effect on prolonging the fatigue life of parts.