Rolling mill bearings, as the roller system bearings of calendering machines, especially those of aluminum casting and rolling machines, are all lubricated with grease in China. After being used for a period of time, the bearings must be cleaned or maintained regularly to ensure their normal operation. Often, the bearings need to be removed from the bearing housing before detailed cleaning, inspection and maintenance work can be carried out.

For example, common structure one used in aluminum casting and rolling:

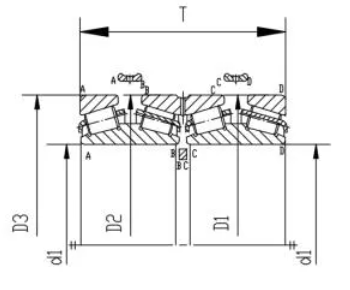

Four-row tapered roller bearings

For four-row tapered roller bearings, due to structural limitations, the inner and outer rings cannot be separated after installation in the bearing housing, especially the disassembly is difficult. Currently, most on-site disassembly still uses the method of tapping the bearing end face with an aluminum or copper rod. This disassembly method has the following drawbacks:

1.The disassembly efficiency is low and the labor intensity is high.

2. It is easy to strike the inner ring or cage, causing deformation of the bearing parts.

3. It is easy to cause the rolling elements to overload and transmit the striking force, resulting in damage to the raceway.

4. Knocking on or hitting flying objects poses certain safety risks.

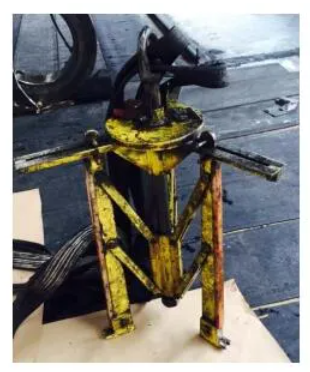

Therefore, it is recommended to use the hydraulic disassembly vehicle device for disassembly work. Compared with the aluminum rod knocking, it has the following advantages:

5. High disassembly efficiency and low labor intensity.

6. It can objectively prevent deformation caused by touching the cage.

7. It can objectively prevent the situation where the rolling elements are overloaded and the striking force is transmitted, thereby avoiding damage to the raceway.

8. Avoid knocking or hitting flying objects, ensuring a high safety factor.

9. It can achieve multiple disassemblies with one machine, and the bearings inside the box have a size difference of about 200mm (width and height).

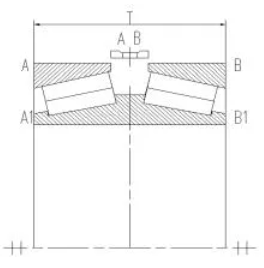

Common Structure Two in Aluminum Casting and Rolling:

Double-row tapered roller bearings are easier to disassemble compared to four-row tapered bearings. However, the disassembly method using aluminum rods also has the aforementioned drawbacks. Therefore, it is recommended to use a hydraulic disassembly vehicle or a three-claw hoisting tool for disassembly.

Because the outer ring of the double-row cone is split, its cross-section is relatively narrow, and the fit with the bearing box itself is a clearance fit. Therefore, the disassembly resistance is relatively small, and it can also be safely and quickly disassembled using a three-jaw hoisting tool.

When disassembling, just lay the firmly fixed bearing housing with the disassembly belt flat, open the bearing box cover that presses the end face of the outer ring of the bearing, and use the crane in combination with the three-jaw lifting tool to lift the end face of the inner ring of the double-row tapered bearing. The inner ring and the rolling element assembly along with half of the outer ring can be removed from the box with the three-jaw lifting tool, and the remaining half of the outer ring can be lifted out in the same way.

Regarding the specific implementation details of the hydraulic disassembly device, it is necessary to determine the structure and function of the final disassembly device by checking the size of the bearing box, the bearing model, and the box structure, so as to ensure the most effective and suitable disassembly function. The DMD Cloud Steel Rolling Service Platform can visit your site on-site to measure and customize efficient and applicable disassembly devices for you!