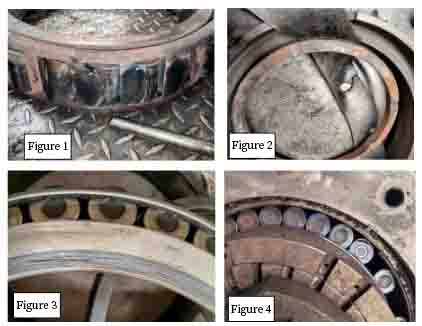

By going to the scene to view the damaged bearing material, as well as the person in charge of the introduction, to understand the site theme overview is as follows:

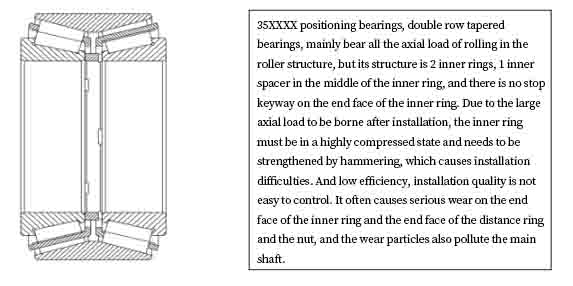

Bearing type: 35XXXX

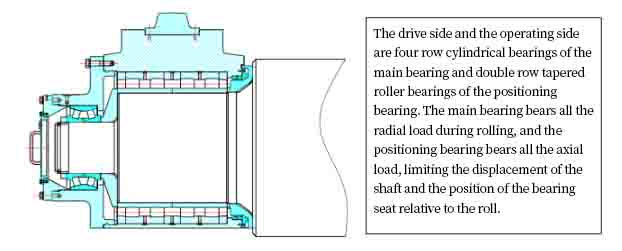

Use parts: operation side and transmission side of support roll;

Lubrication form: oil and gas;

Line speed of mill: 700-1200m/min

Combined with the picture analysis is mainly due to the structural composition of the bearing itself, such as the inner ring locking instability, often cause the end face and contact end wear. Secondly, the large end faces of the rolling body are respectively on both sides of the bearing, which has higher requirements for the amount of lubricating oil. Once the oil is depleted, the friction between the large end faces of the rolling body and the large guard edge of the inner ring is particularly easy to occur (Figure 4), resulting in the fracture of the bearing cage, bearing burn damage and other problems.

As far as possible in the case of little movement to change the bearing size, our technical department believes that the following measures can be taken to improve the service life of positioning bearings:

1. The positioning is changed from the current 35XXXX structural situation to 37XXXX structural situation;

2. Compared with 35XXXX, the structure of 37XXXX has the inner ring as a whole, and the end face of the inner ring is equipped with a stop keyway. Because the inner ring is integrated and has a stop keyway, the inner ring and the shaft are synchronized during operation, which directly eliminates the problem of the end face wear of related mating parts. Unity, high quality and high efficiency.

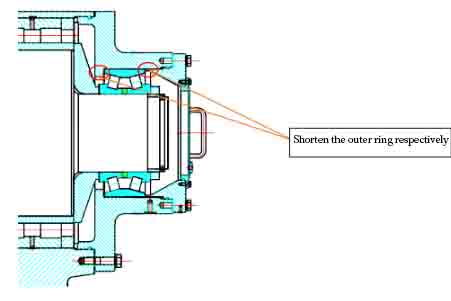

3. When changing the structure, due to the widening of the outer ring width, it is necessary to change the inner end face of the positioning bearing housing and the size of the gland extension, that is, shorten it respectively. Position as shown below.

1, the improvement can reduce the probability of burning;

2, can shorten the overall length of the support roller body, reduce weight;

3, can omit the use of combination nuts, instead of bolts and pressure plates, save costs;

4, can significantly improve the assembly efficiency, quality and reduce labor intensity.

5, In use modification structure drawing and physical pictures: