High chromium bearing steel and carburized steel bearing steel will be used in rolling mill bearings or parts, respectively with different mechanical and physical properties and chemical composition, the use of spectrometers can quickly and accurately identify and distinguish the chemical composition of bearing parts and advantages and disadvantages.

High chromium bearing steel, such as GCr15, is a special alloy steel that contains more chromium elements (usually 1.5% or more), which provides excellent wear resistance and precise fatigue resistance.

High chromium bearing steel is often used in positioning bearings and thrust bearings, such as deep groove ball bearings, angular contact ball bearings, small size double row tapered roller bearings, thrust aligning roller bearings and thrust tapered roller bearings, etc. Most of the FC structure of four row cylindrical roller bearings are made of high chromium bearing steel.

Carburized steel usually has a low initial carbon content, through the carburizing process to increase the surface carbon content, so as to form a hard shell in the surface, bearing surface hardness and high chromium bearing steel hardness is basically the same, while the core hardness is lower, and still maintain toughness. This makes the carburized steel outstanding ability to withstand the impact load, has a high anti-fatigue, anti-surface stripping performance, to maintain a high rolling mill bearing life.

Carburized steel is often used in cold rolling FCD and FCDP four row cylindrical roller bearings, four row tapered roller bearings.

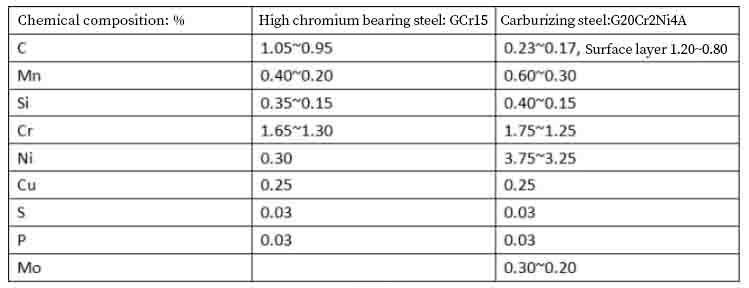

First, we compare the chemical composition of high chromium bearing steel commonly used in rolling mill bearings and carburized steel.

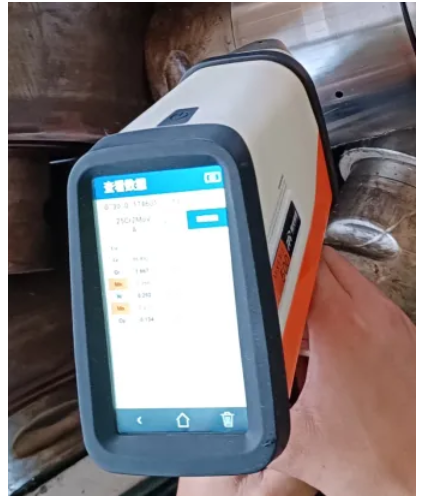

All kinds of bearing steels have the same chemical composition, and the content of alloying elements such as carbon (C), manganese (Mn), silicon (Si), chromium (Cr) nickel (Ni) is high. Carburizing steel is relatively high chromium bearing steel, nickel (Ni) element content is very different, with the continuous progress of testing instruments, the field usually uses the spectrometer to quickly collect bearing surface samples, the detection data compared with nickel (Ni) element content, can quickly identify the bearing parts of high chromium bearing steel or carburizing steel material composition, and distinguish.

When detecting with the spectrometer, the surface of the bearing parts should be wiped, the probe and the detection surface are in close contact, such as the detection surface is not clean, or there is floating rust, or the spectrometer is shaken during the detection, the detection data will have errors, and the data needs to be collected again.

Generally, the chemical composition data collected will be slightly smaller than the laboratory test data, the nickel content is less than 0.3, which can be determined as high chromium bearing steel, and the nickel content of high-quality carburized steel is usually more than 3.