One Customer profile

A metallurgical engineering design institute designed a new steelmaking project scheme for customers, which required the bearing selection of converter tilting reducer.

1. Working condition of converter tilter reducer bearing:

Bearing operating temperature below 40°C;

Thin oil lubrication (gearbox oil);

Left positioning bearing bearing 58 tons of radial force, 30 tons of axial force;

The right free end bearing bears 13 tons of radial force;

Rotational speed n=1.22r/min.

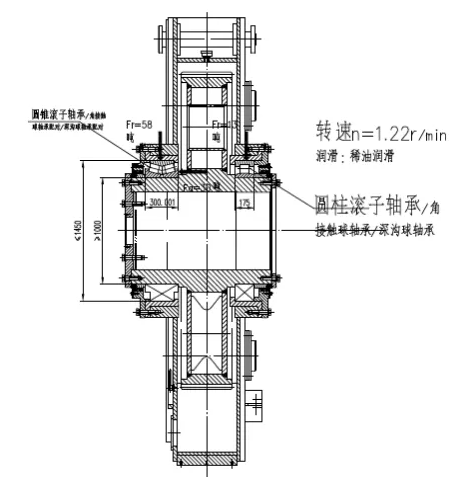

2. The initial reducer design scheme is shown below. The space size of the bearing to be designed is as follows:

Bearing inner diameter ≥1000mm

Bearing outer diameter ≤1450mm

The positioning bearing width is 300mm and the free end bearing width is 175mm

The theoretical service life of the bearing is 10 to 15 years.

3. The design Institute entrusted our company to assist in bearing selection of the converter tilting reducer. According to the bearing configuration and working condition illustration of the reducer, the bearing type configuration and selection priority are as follows: double column cone/single column cylinder; Double row angular contact/deep groove ball; Double row aligning ball/deep groove ball configuration. And validate the new bearing solution for the reducer.

Two Bearing selection according to customer bearing operating conditions and configuration requirements

1. Confirmation of bearing working conditions (technical data provided by users)

Bearing dimension requirements: bearing inner diameter ≥1000mm; Bearing outer diameter ≤1450mm; Fixed end bearing

The width is 300mm and the free end bearing width is 175mm.

Fixed end bearing load: radial load,Fr1=58T=580KN;

Axial load, Fa=30T=300KN.

Free end bearing load: radial load, Fr2=13T=130KN.

Bearing speed: 1.22r/min.

Operating temperature: below 40℃.

Bearing life requirements: 10~15 years = 87,600 ~131400(hours).

2. Initial bearing selection

In the selection of bearings, usually first consider the bearing configuration in the shafting, installation, disassembly of the difficulty, bearing space, size, market value performance and other factors, choose the appropriate bearing structure.

Secondly, the mechanical design life and different durability of various types of bearings are compared, and the bearing size is selected.

In the selection of bearings, not only should consider the fatigue life of bearings, but also choose the appropriate lubrication method, and pay attention to the impact of wear and noise caused by the aging of bearing grease.

Moreover, according to the working condition of the bearing, the design requirements for the accuracy, material, clearance, structure and grease of the bearing are proposed.

According to the bearing configuration diagram and bearing selection priority given by the design institute, the initial bearing selection configuration is proposed as double row tapered roller bearings and single row cylindrical roller bearings, referring to the bearing configuration of similar equipment and the bearing selection scheme for optimizing bearing bearing capacity, installation, disassembly and service performance.

According to the space size of the reducer bearing proposed by the design institute, select the appropriate bearing, referring to the diameter series and width series standards in the bearing size series, first select the φ1030 inner diameter size and φ1310 outer diameter size, and then determine the width size of 300mm and 175mm.

3. Bearing design and main design parameters

According to the selected bearing size, determine the basic bearing type

Double row tapered roller bearing 3506/1030 (d*D*C*T) : φ1030*φ1310*220*300

Single row cylindrical roller bearing NU6/1030M (d*D*B) : φ1030*φ1310*175

3506/1030 Main design parameters:

Rated dynamic load Cr:8000KN

Rated static load Cor:24800KN

Load factor e=0.43

Single row cylindrical roller bearing NU6/1030M Main design parameters:

Rated dynamic load Cr:5700KN

Rated static load Cor:14300KN

4. Equivalent load calculation

Double row tapered roller bearing 3506/1030

Because Fa/Fr1=300/580=0.52 > 0.43(e)

So the equivalent coefficient: X=0.67, Y=2.34

Equivalent load P1=0.67*580+2.34*300=1091KN

Single row cylindrical roller bearing NU6/1030M

Equivalent load: P2=Fr2=130KN

5. Bearing rated dynamic load checking

Check the rated dynamic load of the bearing according to the user's life requirements and working conditions of the bearing (bearing life is checked according to the rated dynamic load Cr of the bearing for 15 years)

Double row tapered roller bearing rated dynamic load checking calculation:

Cr≥ (L 10*60*n/106) 0.3*P= (131400*60*1.22/106) 0.3*1091=2150KN

Compare 3506/1030 rated dynamic load: Cr=8000KN>2150KN

Single row cylindrical roller bearing rated dynamic load checking calculation:

Cr≥ (L 10*60*n/106) 0.3*P= (131400*60*1.22/106) 0.3*130=256KN

Compare NU6/1030M rated dynamic load: Cr=5700KN>256KN

Conclusion: The fatigue life of the two kinds of bearings selected by empirical calculation can meet the requirements of users.

6. Bearing rated static load checking

Because the bearing speed is 1.22rpm, it is a low-speed rotation, and the main damage form of the bearing is no longer fatigue

Failure is the plastic deformation generated at the contact between the rolling element and the raceway, and the static load will be too large in the raceway table

The surface is pitted, so it is necessary to check the rated static load of the bearing.

Bearing equivalent static load is calculated according to equivalent dynamic load, that is

Po1=1091KN

Po2=130KN

Bearing static load coefficient fs

3506/1030 fs=Cor/Po=24800/1091=22.7>2

NU6/1030M fs=Cor/Po=14300/130=110>2

Static load safety factor of roller bearing is :fs=2

Conclusion: The rated static loads of the two kinds of bearings selected by empirical calculation meet the requirements of users.

7. Bearing clearance selection

According to the working condition of the bearing of the converter tilter reducer, the working temperature of the bearing is lower than 40°C, and the C0 basic group clearance is selected.

Three Converter tilter reducer bearing technology solution

1. Bearing type:

Double row tapered roller bearing 3506/1030 (φ1030*φ1310*220*300)

Rated dynamic load Cr:8000KN; Rated static load Cor:24800KN

Single row cylindrical roller bearing NU6/1030M (φ1030*φ1310*175)

Rated dynamic load Cr:5700KN; Rated static load Cor:14300KN

2. Countersign drawings and share technical solutions

Through communication and discussion, the final selection of bearings and technical solutions were shared with the design institute, which met the design requirements of the converter tilter reducer bearing. The design institute improved the internal structure design of the reducer according to the bearing drawings and dimensions.