During the disassembly and assembly of the roller bearings, as well as during the transportation and lifting of the bearing housing, if the operation is improper, it may cause impacts to the raceways and rolling elements of the bearings. Axial scratches, dents, and pseudo-pressures will be formed on the surface of the raceways or rolling elements. These damages will continuously expand at the damaged areas during the rolling process of the rolling mill and result in obvious peeling at the affected areas.

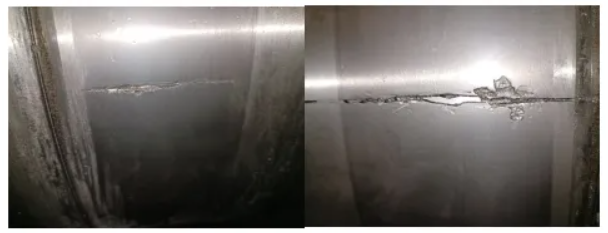

On the inner ring of the bearing near the roller surface, there is an axial damage that is 180° symmetrical. One area has a deep scratch and peeling, and another area has formed a through crack in the inner ring due to peeling and stress concentration at the scratch mark. The analysis indicates that this is caused by improper lifting and operation when the bearing housing was assembled onto the roller during installation.

Now, the inner ring raceways of four rows of cylindrical roller bearings for the supporting roller are equipped with guiding slopes. This design facilitates the periodic disassembly and assembly of the roller. The surface curve design of the rolling elements also prevents the rollers from being scratched by the corner of the bearing. The corner of the rolling elements does not come into contact with the raceway, avoiding the stress concentration and peeling caused by the corner scratch of the rolling elements.

During the process of installing the bearing housing onto the rolls, due to the tilt, the chamfers of the rolling elements collided with the inner raceway surface of the inner ring, resulting in axial scratches. During the rolling process, axial long strip-shaped deep peeling would occur at the scratch locations. When peeling occurs and debris is shed, circular comet-shaped scratches and pits may also be caused by foreign objects, or the damage may expand to large-scale scratches and peeling due to the influence of foreign objects.

The outer raceway load area of the bearing has experienced peeling. The peeling phenomenon is that there are six distinct point-like or strip-like peeling areas outside the large-scale peeling zone. The analysis suggests that during the disassembly, assembly, or hoisting process of the bearing, due to improper operation, the raceway surface was abraded or scratched or deformed, and peeling occurred at the damaged areas during use.

Double-row conical roller bearing with large cone angle, roll thrust bearing, four equal-section cage mounting holes. Two lifting tools were used for lifting, but the bearing was skewed during the lifting process, causing deformation of the cage. The bearing was sent to the factory for repair.

Large rolling bearings are generally designed with lifting holes, which are located on the bearing rings or cages. During the lifting process of the bearings, the number of lifting tools should be arranged according to the actual number of lifting holes, and the lifting straps should also be of the same length to avoid skewing or the bearings from falling during the lifting process.

The center roll die-set ring was heated and installed manually. Due to insufficient installation experience and inadequate heating temperature, the installation was not properly done. After hammering, hammering marks were left on the end face of the die-set ring and the surface of the roll neck, which affected the positioning accuracy of the bearings. The inner ring of the four-row tapered roller bearings was not pressed tightly, and there were traces of runout between the inner diameter and the roll neck.

The fit tolerance between the inner ring of a large four-row cylindrical roller bearing and the roll neck of the rolling mill is usually p6, or r6, or s6. After the hot-rolled roll wears out, it is still installed and used. However, due to insufficient interference fit of the bearing inner ring, after the roll is run out of place, factors such as eccentricity of the raceway or large local stress caused by this affect result in the axial fracture of the inner ring.

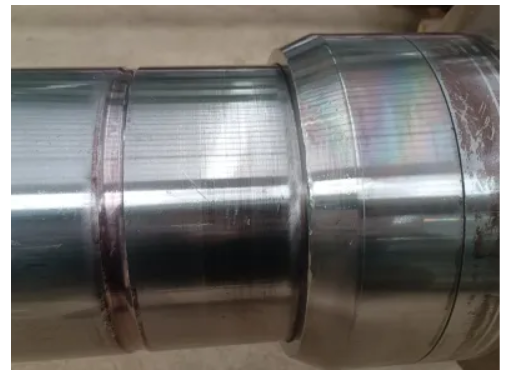

The four-row cylindrical roller bearings of the supporting rollers were removed from the bearing housing using a press. The removal process was simply completed without setting up any special protective bearing fixtures. During the removal, due to the uneven distribution of pressure on the bearing end faces, skewing occurred. At the same time, when the outer ring on the inner side was skewed, the two bearing outer rings would form a self-locking state, unable to rise or fall. Generally, after skewing, the bearing outer rings would crack or be damaged and could no longer be used. The inner hole of the bearing housing would also suffer certain damage, such as scratches or wear.

During the removal process, a suitable sleeve was used to ensure uniform force on the inner side bearing end face. The removal was carried out gently by hand, and the depth was monitored at any time using a depth gauge. There was a bearing platform at the lower end to ensure that the bearing would not be damaged during the fall. By refining the removal operation process, the damage to the bearings and the bearing housing caused by the removal operation was reduced. Comprehensive tooling preparation and rich experience in bearing assembly ensure that the roller bearings can be installed correctly each time during the bearing installation and maintenance process. The bearing raceways will not be damaged or knocked, and the bearings will thus be more durable and have a longer service life.