Foreign object intrusion is the most common type of bearing damage to roll bearings. Irregular pits of varying sizes appear on the raceways and the surfaces of rolling elements, or the large end faces of rolling elements are scratched or ground, accompanied by deep grooves. These bearing damage phenomena are all due to the fact that foreign objects have invaded the interior of the bearings in the particularly harsh operating environment of the rolling mill. These foreign substances include cooling water, oxide scale shed from rolled materials, sand and gravel, dust, as well as iron filings left in the oil circuit after machining inside the bearing housing, metal cutting residues from the bearing processing, and wear and shedding of bearing components, etc.

The following are the bearing damage phenomena of the rolls encountered at the customer's site due to foreign object intrusion:

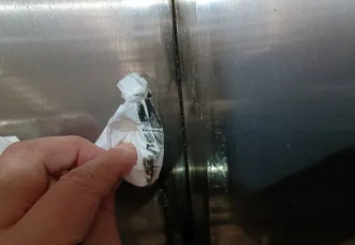

After the cold-rolled support roller shaft is used to grind the inner ring of the bearing, there are grinding wheel shavings and metal iron shavings left in the gap in the middle of the inner ring. Before the bearing assembly, they were not cleaned thoroughly. During the rotation of the inner ring of the bearing, they enter the working area of the bearing along with the oil and gas lubrication, causing many tiny pits on the inner ring raceway.

For this reason, during the installation of new bearings and each maintenance cycle of the roller bearings, the surface conditions of each component of the bearings should be inspected. When wear and detachment of bearing components are found, the bearings should be removed, cleaned with kerosene and then reassembled.

The surface of the rolling elements of the cold-rolled support roller bearings, due to long-term use, has shed substances entering the working area. After being crushed, pits are formed. If used continuously, it will develop to the point where peeling occurs at the edge of the pits. Each periodic maintenance is of great significance. If an increase in pits inside the bearing or foreign objects are found, the external components of the bearing must be disassembled and thoroughly cleaned.

The end face of the four-row cylindrical roller bearing of the support roller of the copper plate and strip four-high mill and the outer ring flange are subject to sliding friction. The roller bearing is not maintained periodically. After long-term use, there will be scratches and wear on the bearing. Grease lubrication will prevent the worn debris from being removed from the working area of the bearing, causing the end face of the rolling element to wear more severely due to the influence of foreign objects. Severe wear will form grooves, affecting the axial clearance of the bearing. After a period of rolling, the bearings of the rolls will all suffer a certain degree of damage. Periodic maintenance, disassembly and assembly of the bearings, inspection of the damage condition of the bearings, and replacement of the load area are conducive to reducing the aggravation of bearing damage, effectively extending the service life of the bearings, and avoiding severe bearing burning of the rolls.

When the inner raceway is damaged by the bearing, the wear and shedding substances invade the contact area between the rolling elements and the raceway, causing pits and wear on the raceway. In severe cases, it may result in deep damage or spalling.

Grease lubrication, due to the failure of the seal of the bearing housing of the support roller, the cooling water and oxide scale of the hot-rolled plate and strip invade the bearing box. The raceway on the side close to the roller surface, due to the failure of lubrication, causes the bearing to heat up, the rolling elements and raceways to wear, and the raceway to rust. In severe cases, it may cause the roller bearing to seize and burn out. The correct maintenance is to check whether the sealing ring has lost its sealing function, especially the lower roller bearing housing, which should be inspected and replaced frequently to prevent water and oxide scale from entering. Through technological transformation, a waterproof sealing structure is adopted. Oil-gas lubrication will enhance the lubrication effect of the bearings and effectively reduce the intrusion of cooling water and oxide scale.

The bearing housing of the hot-rolled sheet and strip support roller, due to the old grease adhering to the oxide scale and other foreign substances of the rolled sheet near the sealing ring, when the new and old greases are mixed, it will cause the grease to contain particles and moisture. The grease will lose its function of isolating the oil film on the contact surface between the rolling elements and the raceway, resulting in the failure of the grease and causing the rolling elements and raceway to scratch and peel off. The correct maintenance is to discard the discolored old grease, replenish and add new grease, and ensure that the grease components inside the bearing are clean. Prevent foreign objects from entering and causing abnormal damage to the roller bearings.