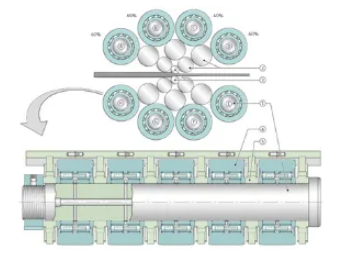

Backing bearings are widely used in the fields of stainless steel, silicon steel, carbon steel multi-roll cold rolling mill and wide plate straightener in the steel industry. Due to its P4 bearing accuracy and strict working conditions, the manufacturing and customer participation of many domestic bearing manufacturers are limited.

Jiangsu Dimond Bearing Co., Ltd. specializes in the production and manufacture of rolling mill bearings, is committed to the research and development of rolling mill bearings, and provides customers with comprehensive rolling mill bearing technical services, imported bearings localization, cloud rolling steel technology and other three areas of customer solutions. With "more durable rolling mill bearing" as the brand positioning, user-centered, doer-oriented, continuous innovation, make rolling more smooth, committed to becoming the leader of rolling mill bearing industry.

Continuous optimization design, process improvement, lean manufacturing, DMD company's backing bearing quality continues to improve, products for more customers to accept and industry promotion.

one. In terms of backing bearing material, in view of ring breakage and fatigue spalling damage, high-quality carburizing steel and high-carbon chromium bearing steel are selected, and more TIMKEN bearing steel 3311 material is selected for key components of rolling mill bearings, which is superior to domestic high-quality carburizing steel in quality, mainly in the content of harmful substances such as: Oxygen, phosphorus, sulfur, lead and so on are far superior to our country's current national standards and domestic carburizing steel. Although the chemical composition of domestic carburized steel test results are within the national metallurgical standards qualified range, but the impurity content is relatively high. This not only brings difficulties to the quality control of heat treatment, but also easily causes the instability of the mechanical properties of the bearing parts and affects the service life of the bearing.

The bearing cage is replaced with manganese brass material cage, which improves the hardness and wear resistance of the cage, and improves the problems of cage foam removal and pocket hole deformation.

two. In the design of backing bearing, the micro-design of bearing structure is optimized to reduce stress concentration, fatigue damage, and reduce the abrasion between rolling body and retaining edge and retaining ring.

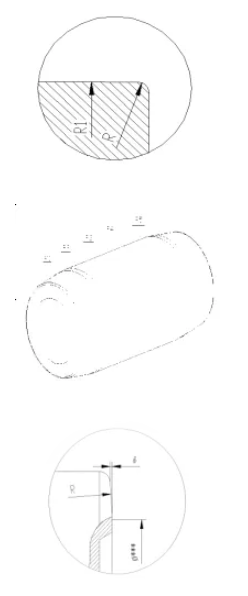

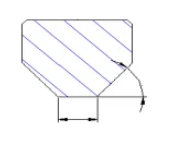

The outer diameter modification, using the large circular arc and the transition between the outer diameter and the chamfer, reduces the stress concentration at the sharp corner of the outer diameter and avoids the outer ring fragmentation phenomenon.

Rolling surface modification design and cage hole improvement design, reduce friction, reduce rolling slide, reduce temperature rise.

The ball base structure of the rolling body and the flange increase the Angle design, a small part of the contact convex design reduces the contact area between each other, the lubrication space increases, the friction is reduced, and the abrasion rarely occurs.

The quality of the spacer ring is very important, and the parameter design of the spacer ring needs continuous summary and improvement. In the work, the baffle will contact with the cage, roller end face, inner ring, etc., collision, friction, serious will cause the baffle abrasion, burr, cage chips. The baffle ring has a separating oil circuit to improve lubrication, and the appropriate Angle of the baffle ring will facilitate adequate lubrication.

Reasonable selection of axial dimensional tolerances of movable retaining ring, retaining rim and spacer ring can control the axial series momentum and clearance of rolling element, reduce the collision and swing between rolling element and cage, and improve the rotation speed of bearing.

Select a new type of combined sealing structure to increase the sealing dust performance and improve lubrication.

Lean manufacturing, improve and solidify the processing technology of backing bearing products, strict product quality control of backing bearing process, 100% process magnetic powder flaw detection, product processing using CNC processing equipment, high-precision inner, outer and raceway grinding machines, CNC vertical grinding, inner raceway super finishing machine, etc., in order to maintain good accuracy requirements of bearing parts.

Strictly implement the ISO9001 standard, check the bearing parts one by one, each bearing each part is numbered separately, so that it can be tracked and queried, 100% product inspection.

In terms of the parameter control of backing bearings, the characteristic parameters such as radial clearance difference, outer ring wall thickness difference, inner ring wall thickness difference, roller group diameter difference and axial clearance are controlled to reach the P4 level rotation accuracy control standard. The radial runout of complete sets of bearings is implemented, and the diameter jump of individual specifications reaches 0.002mm. The H value difference of adjacent bearings in the same group shall not exceed 0.002mm, and the H value difference of bearings in the same group shall not exceed 0.005mm; Bearing outer ring can be repaired and worn more than 3mm; The hardness of the bearing outer ring is 59 ~ 61HRC, and the outer diameter has a certain hardness curve from the outside to the inside.

Carry out the localization of backing bearings and repair of damaged bearings, improve the quality of customer technical service, DMD rely on long-term customer rolling mill bearing service experience, the localization of backing bearings, repair bearing business work in full swing.