The choice of bearing clearance and configuration is a very important part of the motor design, and the choice of a solution that is not clear about the performance of the bearing is likely to be a failed design. Different operating conditions, the requirements for bearings will be different.

1 Deep groove ball bearing the relationship between various clearance

Bearing working clearance calculation according to formula (1), the selection of bearing working clearance, theoretically speaking, in the stable running state of the bearing, slightly negative working clearance, bearing service life is the longest.

△=△0-Δfi-δf0-δt+δw…………………(1)

In formula (1) :

△0——original clearance

Δfi——the amount of clearance reduction caused by the inner ring matching with the shaft

δf0——the amount of clearance reduction caused by the combination of the outer ring and the housing

δt——the amount of clearance reduction caused by the temperature difference between the inner and outer rings

δw——the amount of clearance increase due to load

2 About bearing grease

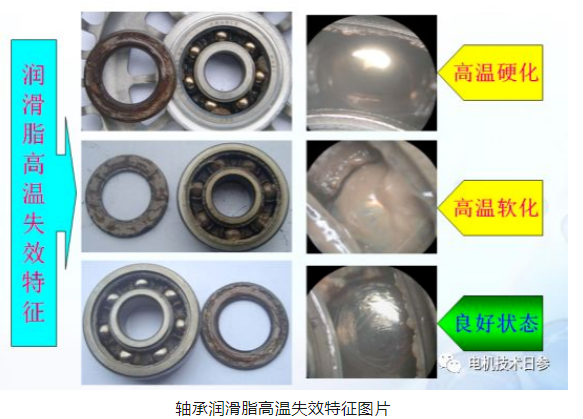

The purpose of bearing lubrication is to separate the rolling body and the rolling surface with a thin oil film, and form a uniform lubricating oil film on the rolling surface during operation, so as to reduce the internal friction of the bearing and the wear of each component and prevent sintering. Good lubrication is a necessary condition for bearing work, analysis of the causes of bearing damage shows that about 40% of bearing damage is related to poor lubrication. The method of lubrication is divided into grease lubrication and oil lubrication.

● Grease lubrication has the advantage of not needing to be supplemented for a long time after filling a grease, and the sealing structure is simple, so it is widely used. Grease is a semi-solid lubricant composed of lubricating oil as base oil, mixed with strong lipophilic solid thickener. In order to improve certain characteristics, various additives are also added.

● Oil lubrication, often circulating oil lubrication, jet lubrication, oil mist lubrication. The lubricating oil of bearings is generally based on refined mineral oil with good oxidation stability and rust prevention and high oil film strength, but various synthetic oils are often used.

3 Motor bearing configuration

The bearing configuration of the rotating parts of the motor (such as the spindle) usually requires two sets of bearings to be supported and the rotating part is positioned radially and axially with respect to the fixed part of the machine (such as the bearing seat). Depending on different application conditions, such as load, required rotation accuracy and cost requirements, bearing configurations can include the following:

● Fixed end and floating end bearing configuration

● Pre-adjusted bearing configuration (fixed at both ends)

● "Floating" fine bearing configuration (floating at both ends)

3.1 Bearing configuration of fixed end and floating end

The fixed end bearing provides radial support at one end of the shaft and axial positioning in both directions at the same time. Therefore, the fixed end bearing must be fixed on the shaft and the bearing seat at the same time. Bearings suitable for use in fixed ends are radial bearings that can withstand combined loads, such as deep groove ball fine bearing, double row or paired single row angular contact ball bearings, self-aligning ball bearings, spherical and roller bearings or tapered roller bearings in combination. Radial bearings that can only withstand pure radial loads, such as solid column roller bearings with one ring without a guard, can also be used at the fixed end when used in groups with another type of bearing (such as deep groove ball bearings, four-point contact ball bearings or two-way thrust bearings, etc.). In this configuration, the other bearing is only used for axial positioning in both directions, and a certain degree of radial freedom must be left in the housing (that is, clearance with the housing should be reserved).

The floating end bearing is only radial support at the other end of the shaft, and must allow the shaft to have a certain axial displacement, so that there will be no mutual force between the bearings, for example, when the bearing expands due to heat, the axial displacement can be achieved inside some types of bearings. Axial displacement can occur between one of the bearing rings and its connected parts, preferably between the outer ring and the bearing seat hole.

There are many different combinations of fixed end and floating end bearing configurations, and the following are some of the more commonly used combinations. For rigid bearing configurations, combinations in which axial displacement can be achieved within the bearing should be used, such as:

(1) Deep groove ball shaft/cylindrical roller bearing

(2) Double row angular contact ball bearings/cylindrical roller bearings

(3) Paired single row tapered roller shaft/cylindrical roller bearing

(4) NUP type cylindrical roller bearing /NU type cylindrical roller bearing

(5) NU type cylindrical roller bearing + four-point contact ball bearing /NU type cylindrical roller bearing

The above combination must minimize the Angle error between the shaft and the bearing seat. If the application situation does not allow, it is recommended to use a combination of self-aligning bearings that can withstand greater Angle errors, such as:

(1) Self-aligning ball bearing /CARB ring roller bearing

(2) Spherical roller shaft /CARB ring roller bearing

These configurations can withstand certain Angle errors and axial displacement, and can avoid internal axial forces in the shafting.