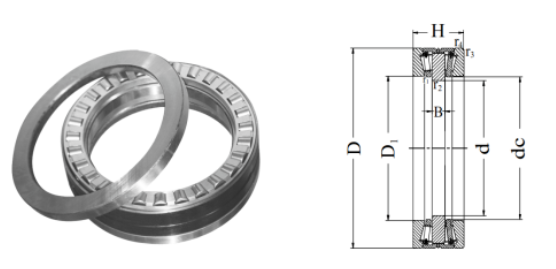

1.Structural composition and characteristics

The bi-directional double-row thrust cylindrical roller bearing is a separable type of bearing, which is respectively composed of a shaft ring, a seat ring, a clearance spacer ring, two rows of circular rolling elements and a cage assembly. It is mainly used in rolling mill as an auxiliary bearing together with multi-row cylindrical roller bearings (four rows of cylinders) to withstand all axial forces generated during steel rolling to limit the two-way axial displacement of the shaft. Prevent the relative displacement of the upper and lower rollers and the dislocation of the slot holes, so as to ensure the shape specification of the rolled material.

Since two-way thrust tapered roller bearings are usually fitted in a loose fit on the roll journal and the roll bearing box, most bearings have one or two positioning slots for the shaft seat. In this way, it is possible to use a key embedded in the positioning slot or similar method to prevent the shaft seat ring from rotating on the shaft, the bearing does not have aligning performance, is more sensitive to misalignment, and does not allow the shaft to tilt the housing axis after installation, and the larger Angle alignment error will produce additional stress, which will shorten the service life of the bearing.

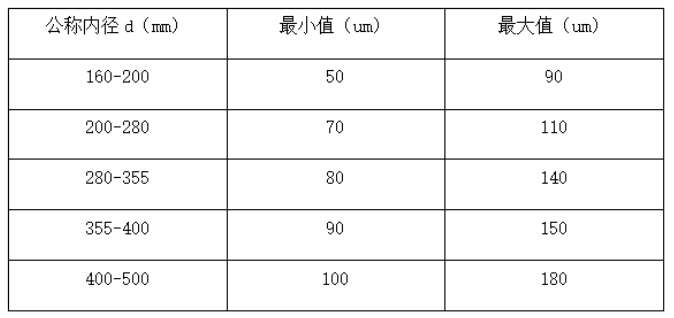

2.Bearing clearance value setting

There is a clearance adjustment ring in the middle of the ring, so the axial clearance of the bearing has been adjusted to a fixed value when leaving the factory. If the customer needs to adjust it during use, the clearance value can be adjusted by increasing and shortening the height of the clearance adjustment ring. At the same time, due to the characteristics of the bearing structure and low limit speed, the bearing is mainly used in the billet, rough rolling and middle rolling parts of the long bar rolling mill, and the bearing mainly bears the axial load and limits the two-way axial displacement of the shaft to prevent the relative displacement of the upper and lower rolls and the dislocation of the slot, so as to ensure the shape specification of the rolled bar. The size of the axial clearance determines the relative momentum of the roll and the amount of slot dislocation, which affects the subsequent rolling process and the quality of the finished product, so the setting of the axial clearance value is particularly critical. According to many years of field experience, the recommended setting value of the axial clearance for DMD bearings is as follows:

Table 1 Recommended value of axial clearance of bi-directional thrust tapered roller bearing for long bar rolling mill

Note: Clearance adjustment can be made by contacting DMD Technical Department

3.Installation precautions

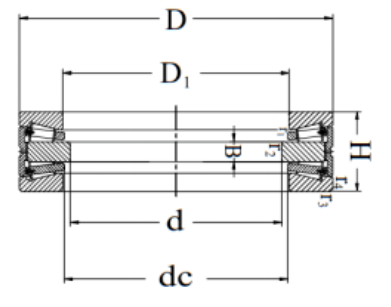

Two-way thrust tapered roller bearings of its three sizes :dxDxH are national standard size, design selection or installation generally will not be inappropriate or wrong, but the D1 value, dC value, that is, the inner diameter of the seat ring and the inner diameter of the cage component, multiple models involve a variety of sizes and the improvement and optimization of each factory standard size is inconsistent with each other. It often leads to interference problems between dC value and shaft shoulder or sleeve outside diameter during installation, so it is necessary to consider D1 value and dC value when designing and selecting or installing, so as to avoid installation interference problems.