1. bearing radial clearance Gr

The arithmetic mean of the radial distance of a ring moving from one eccentricity limit position to the opposite limit position at different angular directions without external load.

2. Theoretical radial clearance

The theoretical radial clearance of the bearing is the contact diameter of the outer ring raceway minus the contact diameter of the inner ring raceway minus twice the diameter of the rolling element to obtain the clearance value.

3. Axial clearance Ga

The arithmetic mean of the axial distance of one ring or washer from one axial limit position to the opposite limit position with respect to another ring or washer without external load.

4. The relationship between radial clearance and axial clearance

Radial bearing also has axial clearance when there is radial clearance. In the original state without load contact, the axial clearance and radial clearance of individual bearing types have different functional relationships related to bearing types. For example, tapered roller bearings Ga=Gr*Cotα(α is the contact Angle)

5. bearing factory internal clearance standardization

C1 is smaller than C2

C2 is smaller than CN basic group clearance

CN basic group clearance

C3 is larger than the basic clearance

C4 is larger than C3

C5 is greater than C4 clearance

C9 Special, non-standard value clearance

For example, the bearing designation 6315/C3 indicates three sets of clearance.

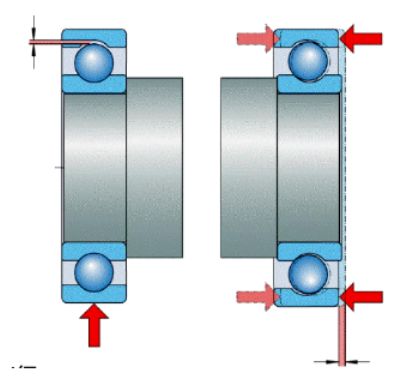

6. bearing installation clearance

After the bearing is installed, the theoretical clearance is subtracted from the expansion or contraction of the ring caused by interference fit when the bearing is installed on the shaft or bearing seat. Usually, the mounting clearance will be less than the original clearance value of the bearing.

7. Working clearance of bearing

Bearing clearance under actual operating conditions.

When the bearings are installed on the shaft and in the bearing seat, the radial clearance will be reduced when affected by the bearing interference fit, such as the expansion of the inner ring and the compression of the outer ring.

When the bearing is working, the temperature difference between the inner and outer rings will also lead to the reduction of radial clearance, but the effect of working load will cause elastic deformation between the ring and the rolling element, which will increase the clearance.

In general, the working clearance will be greater than the installation clearance and less than the original clearance. For the selection of bearings, it is very important to determine the mounting clearance.

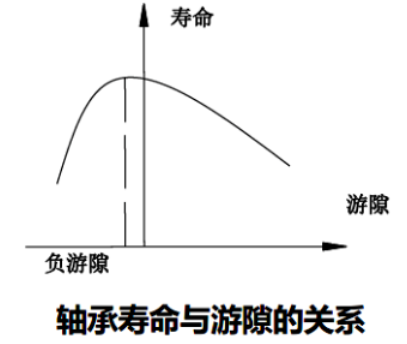

8. bearing clearance affects bearing life

Bearing clearance has influence on bearing fatigue life, temperature rise, vibration, noise, etc., and should be selected reasonably.

Bearing installation clearance through a certain amount of negative clearance value requirements, can make the bearing have a certain preload, can improve the bearing rigidity, can also improve the service life of the bearing. When the preload exceeds the upper limit of the optimal range, the bearing rigidity increases little, while the friction and heat increase sharply, and the bearing life decreases sharply. When the clearance is too large, the number of rolling elements bearing the load is small, and the maximum load borne by a single rolling element will increase, and the bearing life will also decrease.

Rolling bearing clearance is an important characteristic parameter of the bearing, which directly affects the performance of the bearing. It is of great significance to select the appropriate clearance reasonably according to the service conditions of the bearing.