Deep groove ball bearings cannot withstand heavy axial loads, so angular contact ball bearings (also commonly known as thrust bearings) are mainly used as positioning bearings in vertical motors. Whether in single-row or double-row design, angular contact ball bearings have a high axial load-carrying capacity and speed performance. Today, Ms. Can would like to talk to you all about vertical motor bearings.

Angular contact ball bearings come in several types: 7000C type (∝=15°), 7000AC type (∝=25°), and 7000B type (∝=40°). This type of bearing generally has inner and outer rings that cannot be separated and can withstand combined radial and axial loads as well as axial loads in one direction. The capacity to withstand axial loads is determined by the contact Angle. The larger the contact Angle, the higher the capacity to withstand axial loads. This type of bearing can restrict the axial displacement of the shaft or housing in one direction.

Single row angular contact ball bearings are mainly used in machine tool spindles, high-frequency motors, gas turbines, centrifugal separators, front wheels of small cars, pinion shafts of differentials, booster pumps, drilling platforms, food machinery, dividing heads, welding machines, low-noise cooling towers, mechanical and electrical equipment, painting equipment, machine tool channel plates, arc welding machines and other equipment. The commonly used bearings for vertical motors are single-row angular contact ball bearings.

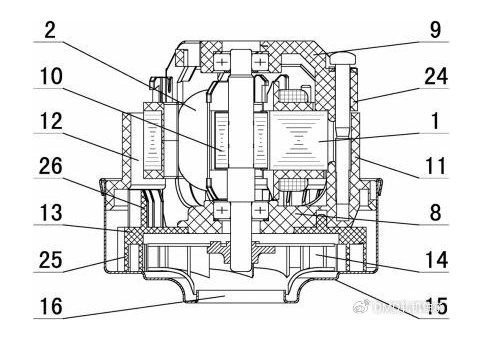

The bearings installed on vertical motors are related to the motor's own power and center height. Deep groove ball bearings are generally used for vertical motors of H280 and below, while angular contact bearings are required for motors of H315 and above. High-precision and high-speed bearings usually have a contact Angle of 15 degrees. Under the action of axial force, the contact Angle will increase.

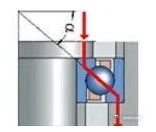

When angular contact ball bearings are used in vertical motors, they are generally installed at the non-shaft extension end to ensure that the shaft extension end bearing can withstand the radial force requirement. However, angular contact ball bearings have strict directional requirements for installation. It is necessary to ensure that the bearings can withstand axial forces in a downward direction, that is, consistent with the direction of the rotor's gravity.

Simply put, if the angular contact ball bearing is on top, it is necessary to ensure that the bearing "hangs" on the rotor. If the angular contact ball bearing is located at the bottom, it is necessary to ensure that the bearing can "support" the rotor.

However, on the premise of meeting the above functional requirements, the assembly processability of the end cover must also be considered, that is, the external force applied during the assembly of the end cover should be consistent with the axial force that the bearing can withstand (the axial force directions that the inner and outer rings of the angular contact ball bearing can withstand are opposite), otherwise the bearing will be pushed apart from the frame.

According to the above rules, when the shaft extension of the vertical motor is facing upwards, the angular contact bearing is installed at the non-shaft extension end, which not only meets the axial force but also ensures the assembly processability of the end cover. When the shaft of the vertical motor extends downward, the angular contact bearing should also be installed at the non-shaft extension end. However, when assembling the end cover at this end, corresponding measures must be taken to ensure that the bearing is not damaged.