The main reason for the damage of the bearings of the four-high rolling mill for hot-rolled strip steel in a certain steel plant in Shandong is the excessive radial and axial loads they are subjected to during operation. The non-parallelism of the axes of the work roll and the support roll causes the axial relative sliding of their contact surfaces, thereby generating a large axial sliding friction force. During the rolling process, the rolled piece deviates from the rolling center line, resulting in uneven radial loads on each row of bearings. As a result, the radial load on a certain row of bearings is often overloaded, leading to the damage of the entire row of bearings. Therefore, it is necessary to study the force analysis of the bearings of the four-high rolling mill, the stability of the rolling mill frame and other aspects, modify the bearings and repair the frame to improve the equipment accuracy, so as to increase the service life of the rolling mill bearings and reduce abnormal damage.

There are a total of 6 four-roll finishing mills in a certain steel strip plant. The working roll bearings of each mill are 2097938 four-row tapered roller bearings, and the supporting roll bearings are a combination of 6890250 four-row short cylindrical bearings and 1060 deep groove ball thrust bearings. Continuously track the rolling specifications and steel grades at the production site, as well as the transmission stability of the mechanical and hydraulic systems. Continuously track and statistically analyze the service life of the roll bearings. Continuously disassemble and inspect each burned bearing for analysis. It was found that the bearing damage of the work roll 2097938 mainly occurred in the row of bearings on the roll diameter side close to the operating side of the rolling mill, which was damaged first, resulting in the damage of the entire row of bearings. The main bearing of the support roller 6890250 is the breakage of the outer ring and rolling elements of the four-row short cylindrical bearing.

1 Analysis of the Causes of Roll Bearing Damage

1.1 Analysis of the Causes of Bearing Damage of Work Roller 2097938

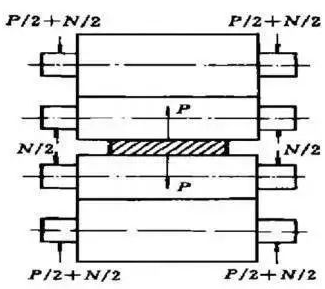

Continuous disassembly inspection and analysis were carried out on each burn-off bearing. Combined with the life tracking statistics of the burn-off bearings, the steel grades and specifications rolled, as well as the stability analysis of the rolling mill equipment and hydraulic system operation, it was found that the main occurrence of bearing burn-off on the work roll 2097938 was in a certain row of bearings at the fixed end of the operating side of the rolling mill, while the burn-off of the free end bearings on the transmission side was rare. Moreover, from the perspective of burn damage, the bearing lubrication is good, but the outer ring and cage of the bearing are broken, and the rolling elements of some damaged bearings are also broken. Figure 1 shows a simplified diagram of the force analysis of the work roll and the support roll of a four-high rolling mill. From the analysis of the force conditions, it can be seen that during the rolling process of the strip steel product, the deformation resistance of the rolled piece is mainly transmitted from the work roll to the support roll, and the axial force of the rolling is mainly transmitted from the friction between the rolled piece and the work roll to the work roll. That is to say, the bearing of the work roll 2097938 is subjected to more axial force during the rolling process, while the bearing of the support roll 6890250 is subjected to more radial force during the rolling process.

The inspection and analysis after disassembling the damaged bearing on site are consistent with the theoretical analysis. When the rolling force of the produced strip steel is large and the stability of the frame system is poor at this time, the rolling axial force will have a significant impact on the fixed end bearing of the work roll, causing damage to the work roll bearing. Therefore, it can be concluded that the damage to the work roll bearing is mainly caused by the large axial force. Of course, any four-high rolling mill will generate rolling axial force during the rolling process. Since the rolling mill stand of a certain steel strip plant was put into operation, it has been in use for a long time. The shape and position tolerance deviation between the working roll window and the support roll window of the stand is relatively large, and the non-parallelism between the center of the stand window and the roll axis is relatively large, with a large cross Angle. Therefore, a large axial force is bound to be generated in the rolling process as shown in Figure 1.

In addition, there are other reasons for the damage of the work roll bearings. For instance, if the rolled piece deviates from the rolling centerline during the rolling process, it will also cause the load on each row of the work roll bearings to be unbalanced, resulting in one row of the bearings being overloaded and damaged first, and thus leading to the damage of the entire bearing. For instance, during the assembly process of the rolls, improper adjustment of the clearance between the four rows of tapered rollers of the work roll bearings and the outer ring of the bearings can also cause damage to the bearings due to uneven loading.

1.2 Analysis of the Causes of damage to the bearing of the support roller

As can be seen from the previous analysis of the force on the rolls, the support rolls mainly bear the radial force during rolling. Due to the limited size of the frame arch in a certain steel strip plant, the bearing selection for the support rolls is 6890250 four-row short cylindrical bearings. The bearing damage phenomena are basically the fragmentation of the rolling elements and the peeling off of the outer ring of the bearing. From the damage phenomenon, it can be analyzed that the cause of the bearing damage of the support roller is mainly overload fatigue damage.

2 Improvement measures to reduce damage to roller bearings

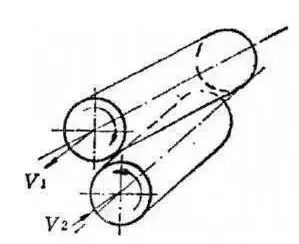

After the rolls are installed in the frame, due to improper control of the shape and position tolerance of the frame window, wear of the bearing seats of the working rolls and support rolls, low grinding accuracy of the rolls, large deviation between the inner and outer sides of the rolling mill base plate, excessive offset of the rolling centerline, and inconsistent adjustment of the roll gap between the inner and outer sides of the rolls, all these will cause spatial intersection of the roll axes. As shown in the following figure.

When there is a large spatial cross between the rolls, the axial force on the working roll bearing is particularly obvious, and at the same time, the radial force eccentric load on the support roll bearing is also greatly affected. There is a difference in damage to both the working roll bearing and the support roll bearing.

In view of the current situation of a certain steel strip plant, to reduce the abnormal damage of the bearings of the four-high rolling mill, the following improvement measures need to be taken:

(1) Starting from enhancing the stability of the frames: On the one hand, during daily maintenance, dedicated personnel should be assigned to systematically inspect the window dimensions of the frame arches of the six frames. If the deviation of the window dimensions is found to be more than 0.8mm, the rolling mill liners must be replaced to control the window dimensions. During annual maintenance, major overhauls should be carried out on the frame arches of the rolling mill to improve the accuracy of the frames. On the other hand, inspect the balance cylinder of the working roller and the balance cylinder of the upper support roller to reduce leakage and internal leakage. And check the elevation of the inner and outer bottom plates of the rolling mill, with the elevation difference controlled within 0.5mm.

(2) Starting from improving the precision of bearing housings and the assembly quality of rolls: Every six months, inspect the external dimensions, symmetry, inner hole dimensions, and ellipticity of all roll bearing housings. Bearing housings that exceed the tolerance range of the drawings should be repaired or scrapped and replaced. Each roll should be assembled in accordance with the specifications and marked, recorded and statistically analyzed to facilitate traceability and cause identification.

(3) Enhance the grinding accuracy of the roll car, and keep the roundness and ellipticity of the rolls within 0.03mm.

(4) Enhance the level of production operation: On the one hand, control the size of the incoming material entering the four-high mill for rough rolling to reduce the impact force of the rolled piece on the rolls; On the one hand, improve the balance of the reduction on both sides of the rolling centerline of the four-high rolling mill, and evenly distribute the reduction in each stand to effectively control the balance of the rolling force of the rolled pieces.

(5) Improve the roller bearings: Redistribute the thickness of the rolling elements and inner and outer rings of the working roller 2097938 bearing to enhance its ability to withstand axial force. The bearing of the support roller 6890250 was modified to 6890260, and at the same time, the material of the support roller bearing GCr15 was improved to carburized steel.

3 Closing remarks

Through the implementation of the above improvement measures and the tracking of their application effects, it was found that the online burnout rate of the rolling mill bearings decreased from the original 5.7 pieces per 10,000 tons to 3.5 pieces per 10,000 tons, with a reduction rate of 38%.