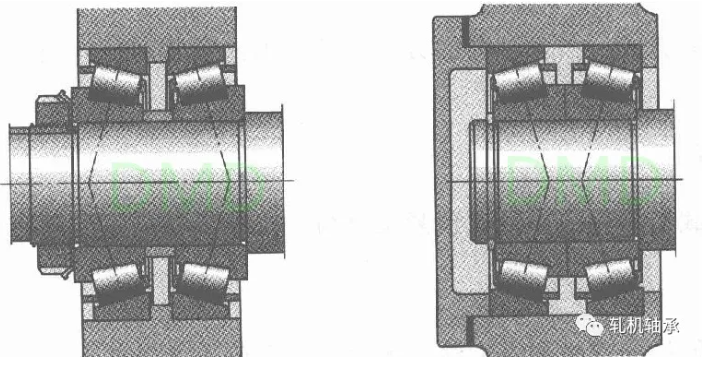

Generally, rolling bearings have a certain amount of clearance when in operation. However, to achieve a specific purpose, when configuring bearings, certain adjustment methods are adopted to make the bearings obtain a certain internal load and be used in a negative clearance state. This usage method is called preloading. Preloading can enhance the rotational accuracy of bearings, increase the rigidity of the bearing assembly, and reduce the vibration of the shaft during machine operation.

The above picture shows the preload of a rolling bearing

The purpose of pre-tightening:

1. Improve rotational accuracy. After the bearing is preloaded, the internal clearance is eliminated. Each rolling element bears a certain preload and supports the rings from all directions, which can improve the rotational accuracy, enable the shaft to be correctly positioned in the radial and axial directions, and enhance the rotational accuracy of the shaft.

2. Enhance stiffness. The contact points between the rolling elements and the raceways are all elastic contacts, and the rolling elements can be regarded as springs. Bearings with clearance are supported by only a few springs in the direction of force application. After preloading, the bearing is supported by springs in all directions and has a certain preload amount. The number of rolling elements bearing the load is greater than when there is clearance, thus the rigidity can be improved. In ball bearings, the relationship between the contact deformation of the ball and the raceway and the load is nonlinear. As the preload increases, the contact stiffness also increases.

3. Increase the service life of bearings. After preloading, the number of loaded rolling elements increases, and the load on each rolling element decreases. At the same time, the load can be distributed more evenly on each rolling element, so the service life of the bearing can be prolonged.

4. Enhance the damping of bearings and reduce noise. Preloading establishes a stable oil film between the rolling elements and the raceways, enhancing the damping between them. This can improve the dynamic characteristics of the supporting structure and reduce noise.

5. Improve the dynamic performance of angular contact ball bearings. In high-speed rotating angular contact ball bearings, appropriate preloading can prevent the steel balls from gyroscopic rotation, prevent or reduce the slippage of the steel balls during their revolution, and also control the spin sliding of the steel balls.

6. Suppress vibration marks and friction wear. It is used for vibration-free processing on low-roughness machine tools, or in mechanisms where friction and wear need to be controlled during frequent starts and stops.

7. Control the slippage phenomenon of the rolling elements during their revolution and rotation. Such as radial thrust ball bearings used in high-frequency motors and cylindrical roller bearings on jet engines, etc.

8. Compensate for wear and tear during operation. During operation, bearings may experience an increase in clearance due to wear, and this situation can be compensated for by preloading.

The method of pre-tightening

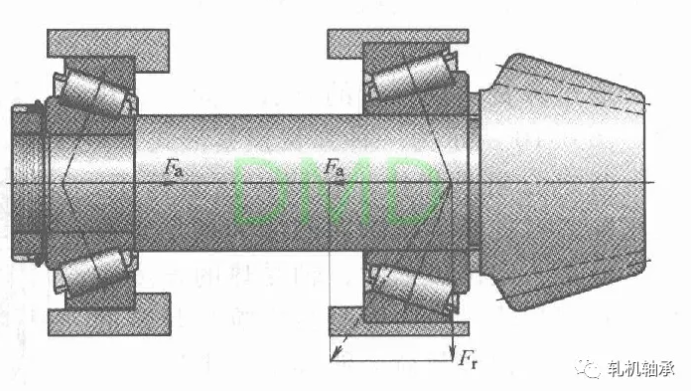

According to the method of applying preload, axial preload can be further divided into positioning preload and constant pressure preload.

I. Axial preload

According to the method of applying preload, axial preload can be further divided into positioning preload and constant pressure preload.

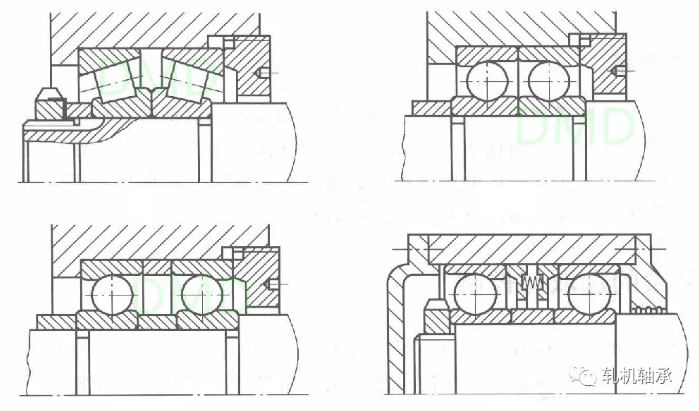

1. Positioning and pre-tightening

The method of applying a preload to a bearing by adjusting the length of the sleeve or the thickness of the gasket is called positioning preload. In pairs of double bearings, a certain amount of pre-deformation is ground off from the end faces of the inner rings of the two paired bearings. After installation, pre-tightening is achieved, which also belongs to positioning pre-tightening.

The axial stiffness of the support system can be significantly improved through positioning preloading. It should be pointed out that for the radial thrust ball bearings with preload applied, the radial stiffness of the support system has also been significantly improved. The relationship between load and deformation of roller bearings is approximately linear. Therefore, applying a preload to a single roller bearing cannot enhance its rigidity. However, for tapered roller bearings installed in pairs, when positioning preload is adopted, the axial stiffness of the support system can be significantly enhanced, just like that of ball bearings. This is because, under preload conditions, the axial working load is jointly borne by the two bearings. The preloading principle of tapered roller bearings installed in pairs is the same as that of ball bearings. Under the same axial working load, the axial displacement of the support system with preloading is only half that without preloading. Therefore, through positioning preload, the axial stiffness of the tapered roller bearing support system can be doubled. The external axial load that ensures a bearing in a preloaded support system is completely free from load is called the unloading load.

The preload structure of the bearing

2. Constant pressure pre-tightening

The method of achieving pre-tightening through springs is called constant pressure pre-tightening. Compared with positioning preloading, under the same preload, constant pressure preloading does not significantly increase the axial stiffness of the support system. However, during positioning preloading, the length change of the shaft due to heating and the radial expansion of the ring due to heating will affect the change of the preload amount. The additional axial load will reduce or untighten the preload amount of one of the bearings, but these problems do not exist during constant pressure preloading. When high rigidity is required, positioning pre-tightening is generally adopted. When high rotational accuracy is required during high-speed operation and it is necessary to prevent the sliding of rolling elements, constant pressure pre-tightening is advisable.

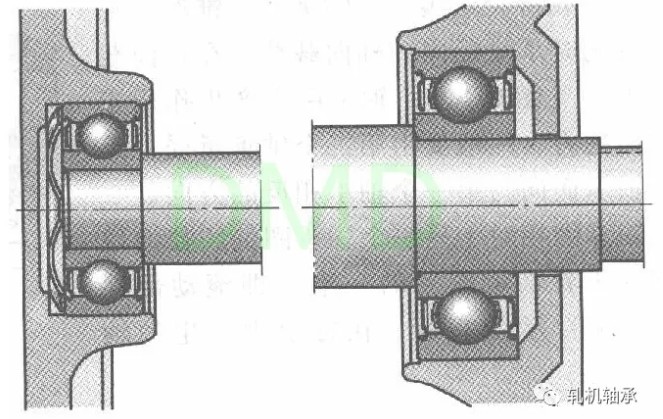

Ii. Radial preload

The method of eliminating radial clearance and achieving pre-tightening by using an interference fit or by using a set sleeve or release sleeve to expand the inner ring is called radial pre-tightening. High-speed radial cylindrical roller bearings with hollow cylindrical rollers have a certain pre-deformation between the rollers and the inner and outer rings after assembly in the bearing structure design, which also belongs to radial pre-tightening. Radial preloading is rarely used. Its purpose is to expand the loading area of the rolling elements, reduce the slippage of the rolling elements, and improve the rotational accuracy, etc.

Radial preload

Iii. Radial Preload

The method of eliminating radial clearance and achieving pre-tightening by using an interference fit or by using a set sleeve or release sleeve to expand the inner ring is called radial pre-tightening. High-speed radial cylindrical roller bearings with hollow cylindrical rollers have a certain pre-deformation between the rollers and the inner and outer rings after assembly in the bearing structure design, which also belongs to radial pre-tightening. Radial preloading is rarely used. Its purpose is to expand the loading area of the rolling elements, reduce the slippage of the rolling elements, and improve the rotational accuracy, etc.