When the stress on the bearing ring is greater than the tensile strength of the material or the fatigue strength limit of the material, the ring causes cracks, and the cracks eventually expand to a certain extent, resulting in a part of the part being completely separated, called cracking or fracture, and the reason is analyzed around the fracture topic:

Taking the inner ring of the four-row cylindrical roller bearing as an example, the inner ring of the bearing needs to fit with the roller shaft diameter to achieve the performance of the bearing with high load and high speed, and the failure of the inner ring fracture often occurs due to the mismatch.

There are mainly the following three situations that can easily lead to the fracture of the inner ring:

1. Excessive interference

When the inner ring and shaft fit interference is too large, the inner ring cracking occurs in two stages;

A. The bearing is hot loaded to the back of the roll neck, and cracks occur during the cooling process of the inner ring before being used on the machine.

B. After the bearing is hot loaded to the roll neck, the cracking occurs when the outside diameter is trimmed before the machine is used.

2. Small interference

When the inner ring and shaft fit interference is small, the inner ring cracking generally occurs in two stages;

A. During the use of the bearing machine, the inner ring and the shaft have relative sliding friction, resulting in the cracking of the inner ring.

B. In the process of running the bearing, the inner ring expansion is greater than the roll neck expansion at the initial stage, and the impact load causes the inner ring to burst when the rolling mill bites and throws steel.

3. Friction of end fitting parts

C. In the process of using the bearing machine, the inner ring and the distance ring have relative sliding friction, resulting in cracks in the section leading to the cracking of the inner ring.

D. During the running of the bearing machine, the inner ring and the dynamic labyrinth and the distance ring have relative sliding friction at the same time, resulting in the fracture of the section leading to the cracking of the inner ring.

In addition to the fracture of the inner ring caused by the above matching, special attention should also be paid to the surface condition of the roll neck matching with the inner ring.

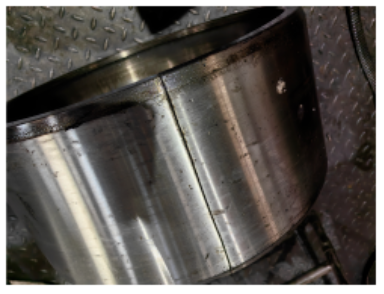

The bearing inner ring is fitted to the roll diameter by hot filling interference. However, due to the surface defects of the roll diameter, interference fit is often destroyed, resulting in inner ring cracking, bearing locking, roll diameter burning and other problems.

A. The surface of the roll neck sinks, and the chamfer (non-contact stress area) is raised.

B. Irregular wear, irregular taper.