Abstract: The reasonable selection of roll bearing in six-high cold rolling mill has a crucial influence on rolling performance of the mill. In order to obtain higher quality sheet, it is necessary to ensure the stability of the mill. Therefore, according to the actual production situation, a reasonable roll bearing configuration is designed to ensure the high efficiency and stability of the rolling mill. In this paper, the design and selection of roll bearings for six-high cold rolling mill are analyzed in detail.

Key words: thin plate; Six high cold rolling mill; Roll bearing

1 Introduction

Roll bearing is an important part of the rolling mill, which is mainly used to support the roll and ensure that it works in the correct position in the frame.

The correct selection of roll bearings is directly related to the rolling energy consumption of the rolling mill, the utilization rate of the rolling mill and the precision of the rolling products [1]. For the high-precision, high-demand, high-yield sheet six-roll cold rolling mill on the market now, if the bearing selection is unreasonable, it will cause huge economic losses to the steel mill, so the selection design should be carried out according to the actual use of the equipment, and the most reasonable and economical roll bearing configuration should be designed.

2 Common roll bearing configuration

At present, the most common roll bearing configuration of sheet six-roll cold rolling mill on the market is: four row cylindrical roller bearings + thrust bearings are generally used for back-up roller bearings; Middle roller bearings generally use four row tapered roller bearings + thrust bearings [2]; Work roll bearings generally use four-row tapered roller bearings, but this is not the most reasonable and practical roller bearing configuration. Therefore, in the design, the best bearing combination should be designed according to the actual working conditions and production needs to meet the actual needs of the roll.

3 New roll bearing selection design

Roller bearing is mainly used to support the roll, it is different from ordinary bearings, it needs to have a large bearing capacity, strong impact resistance and other characteristics [1]. For sheet six roller cold rolling mill, in order to roll products that meet high quality requirements, when the rolling capacity of the mill is more than 30m/min, four row cylindrical roller bearings are better than four row tapered roller bearings, because when the tapered roller bearings are running at high speed, the axial load makes the ball base surface of the roller tightly pressed on the rib, resulting in sliding friction. The temperature of the bearing is very high, which limits the improvement of the rolling speed, and the four-row cylindrical roller bearings do not have this problem. The outer ring of the bearing and the roller bearing cage assembly can be separated from the inner ring, the inner ring interference fit is installed on the journal of the roll, the bearing box and the roll into a separable type, not only can be quickly installed and disassembled, but also can be interchangeable, when the rolling mill changes the rolling program, you can freely choose the combination of the roll and the bearing box, to achieve the purpose of rapid roll change.

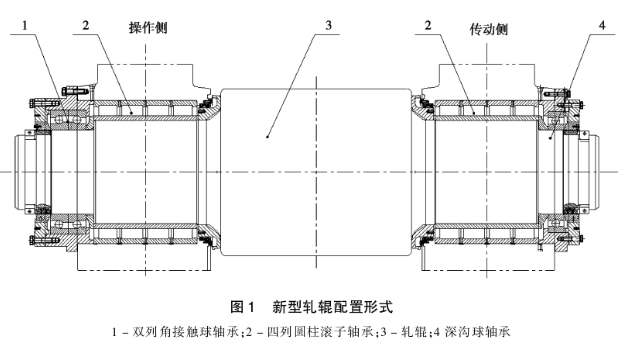

Because the four-row cylindrical roller bearings can only withstand the axial force, it is necessary to configure the appropriate positioning bearings to withstand the axial load of the roll. Combined with the characteristics of high speed and finishing rolling of six-high cold rolling mill, double-row angular contact ball bearings are selected in the operating end and deep groove ball bearings are selected in the transmission end (as shown in Figure 1).

Double row angular contact ball bearings can not only bear radial and axial combined loads and torque loads, but also limit roll axial displacement in two directions, high speed, good rigidity and easy disassembly. Deep groove ball bearings are simple in structure and easy to use, and can mainly bear pure radial force and also bear certain axial load [5]. When bearing pure radial load, the contact Angle is zero, and when the radial clearance is increased, it also has the function of angular contact ball bearings, which can withstand large axial loads. They can not only bear the axial load generated during the working process of the rolling mill, but also play a good role in axial positioning. When the rolling force is suddenly increased under different working conditions during the working process of the rolling mill, these two types of bearings can also share part of the radial load to reduce the damage to the four-row cylindrical roller bearings.

Based on the above analysis, it can be seen that the bearing configuration of "four row cylindrical roller bearing + double row angular contact ball bearing + deep groove ball bearing" can not only adapt to the complex stress conditions of the rolling mill in the working process, but also has high reliability, long service life of the bearing, easy installation and disassembly, and easy control, and can ensure the accuracy of the rolling mill.

4 Conclusions

Through the follow-up service of the new roll configuration form of sheet six roller cold rolling mill, it is found that the production site is in good condition, the bearing runs normally, the disassembly is convenient, the roll change is fast, the maintenance is convenient, the rolling product quality is good, the precision is high, and the production efficiency is greatly improved.

【 Reference 】

[1] HUANG Qingxue, Xiao Hong, Sun Binyu. Design of steel rolling machinery [M]. Beijing: Metallurgical Industry Press. 2007.

[2] Ai Jing. Analysis of thrust Bearing Structure of Each Roll in Rolling Mill [J]. Metallurgical Equipment, 2014 (6) : 46-49.

[3] He Jingnan, Wang Pu. Production technology and equipment of cold rolled strip steel [M]. Beijing: Chemical Industry Press. 2015.

[4] Wu Jie, Yuan Xinghui, He Xuanxin. Analysis of Work Roll Journal Bearing Assembly in Four-high strip Mill [J]. Journal of Bearing, 2013 (7) : 15-17.

[5] Zhang Tiyang. Application of roll bearings in non-ferrous strip Mill [J]. Nonferrous Metal Processing, 2011,40 (3) : 39-41.