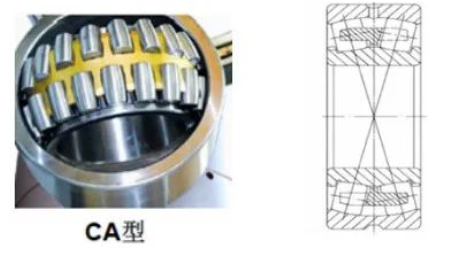

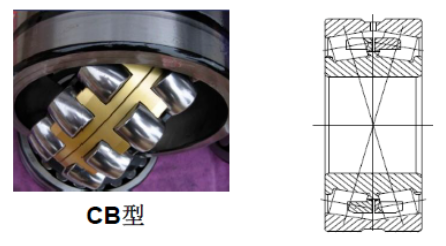

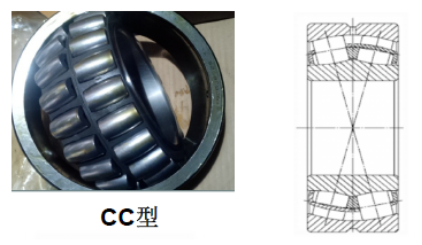

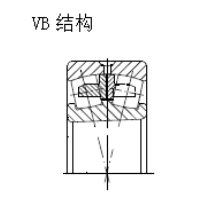

Aligning roller bearings have a variety of different internal structure design types, and used in different occasions, the common structural types in the market are CA, CB, VB, CC, CE and so on.

Aligning roller bearings (commonly known as spherical roller bearings), mainly used in steel, mining, paper, shipbuilding, textile, mill, electric power, fan, washing equipment, transmission gear box and other industries and equipment, is the most widely used in the machinery industry of a class of rolling bearings.

The aligning roller bearing is composed of an outer ring, an inner ring, a rolling body, a cage, a middle ring and other components. The outer ring is a common spherical raceway, the raceway curvature center is located in the bearing center; The inner ring has two spherical raceways, and the center of each raceway is inclined to a certain Angle with the vertical axis of the bearing, which is the contact Angle of the bearing; Two rows of spherical rollers; The cage has mechanical copper protection or iron protection, and also has stamped frame steel cage; Individual structures have a septal design.

Self-aligning roller bearing has the ability to eliminate the misalignment between shaft and bearing box or the influence of shaft deformation and deflection, and can also compensate the concentricity error caused by it.

Symmetrical roller, integrated brass machined cage, inner ring without middle guard edge, with two small guard edge, often used in large size self-aligning roller bearings, in the structural design of self-aligning roller bearings, the most widely used.

Symmetrical roller, two-body separate type brass machining cage, the inner ring has a middle guard, there are two small guard, often used in steel continuous casting and mining crusher and other industries, can withstand axial load.

Symmetrical roller, stamped frame steel cage, inner ring without flange design, movable middle ring, roller self-guiding design. CC type bearing relative to CA structure design, carrying capacity increased by 30%, limit speed increased by 15%, commonly used in small and medium-sized aligning roller bearings, for high speed, high load, high-precision working conditions requirements of equipment, such as fans, steel continuous casting, textile, paper pressing, transmission gear box and other mechanical industries.

Special bearings for vibrating screen and vibration machinery, special structure of two-body separation type brass machining cage, the inner ring has a middle guard side, there are two small guard sides, can withstand axial load, internal and external diameter two-way guidance, anti-vibration and reduce excitation.

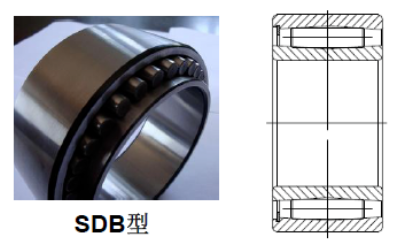

Single-row self-aligning roller bearings, which combine the design elements of self-aligning roller bearings and cylindrical roller bearings, have a large curvature arc of the inner and outer ring raceways, with self-aligning performance and large axial displacement capability, and are used in steel continuous casting segment floating end and textile industry equipment.

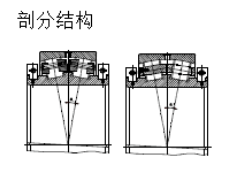

Split aligning roller bearings, outer ring, cage, inner ring adopts split structure design, removable, bearing reassembly at the equipment installation site, avoid long shaft and complex structure equipment and environmental bearing installation complex, reduce maintenance time and cost, often used in ships, steel converter trunnion and other industry equipment.

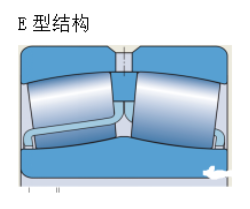

ymmetrical roller, stamped frame steel cage, inner ring without flange design, movable middle ring, roller guide design is different. The structure is better than the CC structure design, has greater load capacity and higher limit speed, and is used for equipment with higher load and speed requirements of aligning roller bearings.

Aligning roller bearings have different structural differences and changes in selection due to different equipment installation and disassembly, maintenance, lubrication or working conditions. For example, the W33 structure with oil holes and oil tanks in the outer ring, the K structure of the cone holes in the inner ring, and the radial clearance C3 selection. To this end, you need to consult the technical manual or consult the manufacturer for a reasonable choice.