With the production of steel bar based high-yield small rolling mill, alloy steel and high quality steel small rolling mill, large coil mill, section mill output increase quantity increase, speed increase, a series of process improvement, especially the popularity and application of short stress rolling mill, manipulator assembly appearance, which requires roller bearing must do the necessary internal structure optimization. To adapt to the new process requirements and assembly requirements.

Based on many years of customized hot rolled bearings such as high wire, bar, section steel, as well as providing on-site technical services, the following structural optimization is carried out for long mill bearings to achieve longer life and more stable operation of bearings.

Bearing radial clearance: bearing rotation accuracy grade p5 is provided, and bearing clearance is all in the middle and lower limit of C4 group, which guarantees the working condition requirements and maximizes the bearing with the largest bearing area and the largest bearing radial load.

For roughing: roughing mill is characterized by slow speed, large load and large impact force. Bearing is required to have high bearing capacity first, which can maximize bearing capacity, such as adjusting internal structure, reasonably increasing large, many and long rolling body, enhancing cage strength, increasing oil storage space and so on. The adjustment of internal structure not only increases the radial bearing capacity, but also enhances the impact resistance.

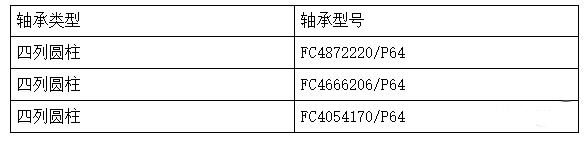

Representative model:

For medium rolling: the speed of rough rolling is faster, the load is reduced, but the impact is larger. It is necessary to adjust the appropriate bearing clearance and outer ring thickness as well as the matching tolerance between the outer ring and the box hole. Similarly, the cage needs to be strengthened and thickened to realize the strengthening of the strength, and finally improve the comprehensive life and operating stability of the bearing.

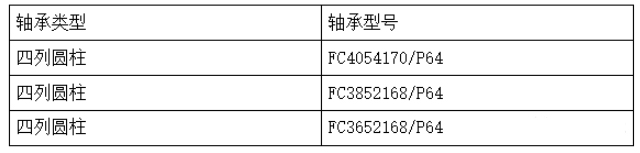

Representative model:

For pre-finishing rolling: Compared with the rolling speed is faster, the load is reduced, but the impact is smaller, especially the bearing cage, more broken teeth, figure-shaped deformation and other problems, so the bearing is required to have a higher rotation accuracy and high strength and friction resistance of the cage, this focus on the cage of the size, tooth thickness and material to improve, such as brass cage change machining steel protection, The cage is designed to increase the wrapping rate of rolling body by 15%. Our company has more valuable experience and examples in this regard. (Welcome to call DMD bearing)

Representative model:

For assembly: especially for manipulator assembly, it is necessary to control the droop degree of the rolling body relative to the outer ring raceway, so as to avoid interference scratches between the bearing rolling body and the inner ring on the roller diameter in the assembly process.